Load-lock type

uGmni-200 and 300:

single-wafer film deposition

and processing system for

advanced electronics

manufacturing

The cluster type system can be equipped with a variety of process modules such as sputtering and etching, which are attached onto the system's common transfer core. "uGmni series" utilizes a common core and other common parts as much as possible, reducing spare parts.

It also uses the same operation panels to improve usability, increasing efficiency of the manufacturing process.

Features

- Able to combine and equip various process chambers: sputtering, etching, ashing and PE-CVD

*Certain combinations may be unavailable depending on the process, so please consult with us. - All above modules to be manufactured by ULVAC

- Compatible with wafers up to Φ300 ㎜

Applications

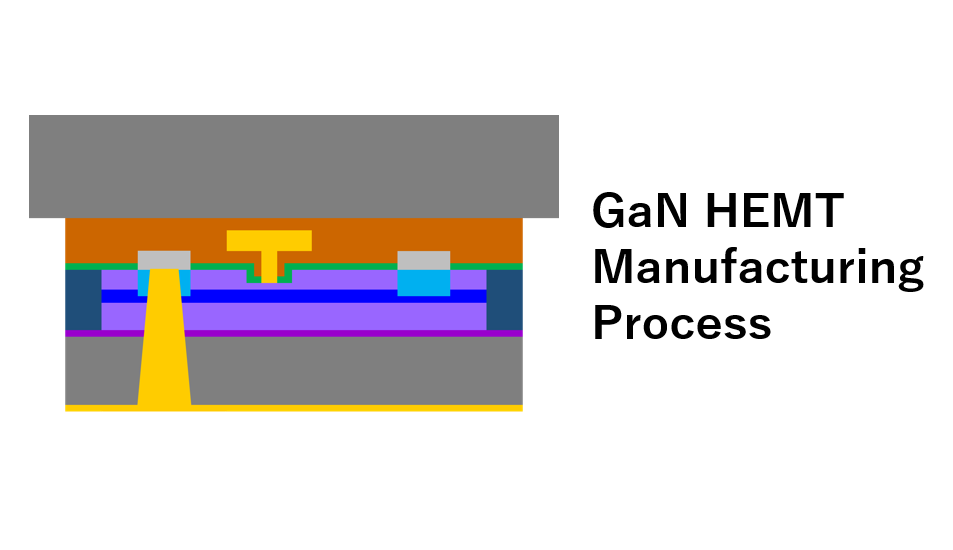

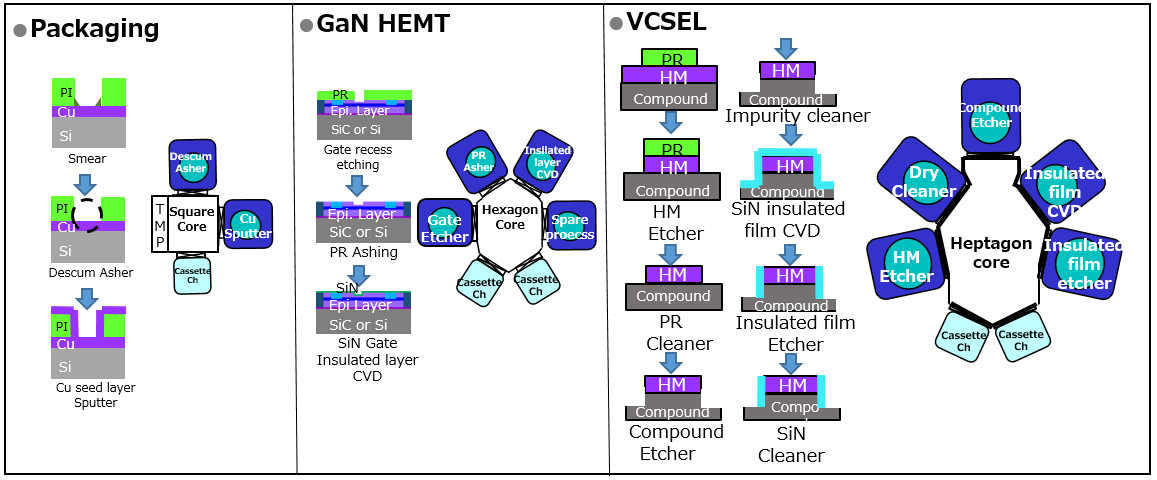

- Power device: seed and metal layer sputtering

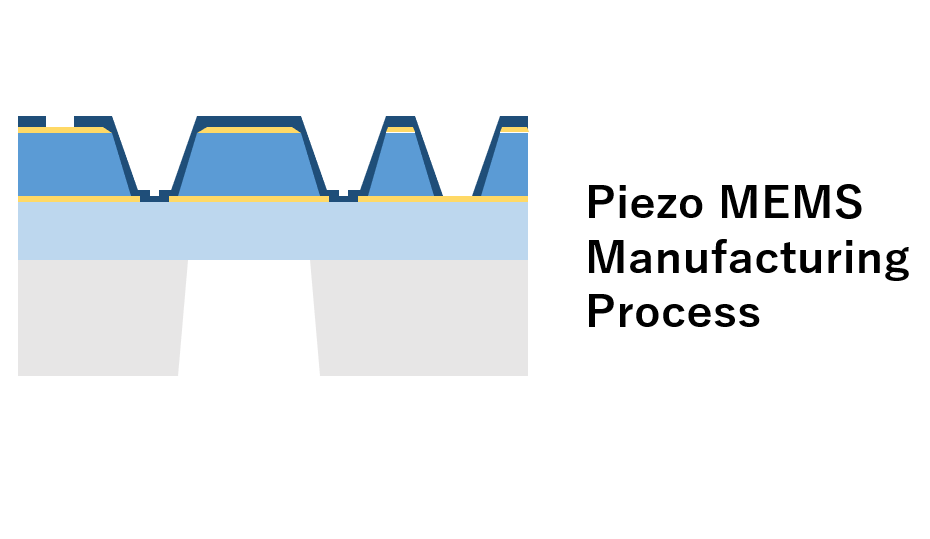

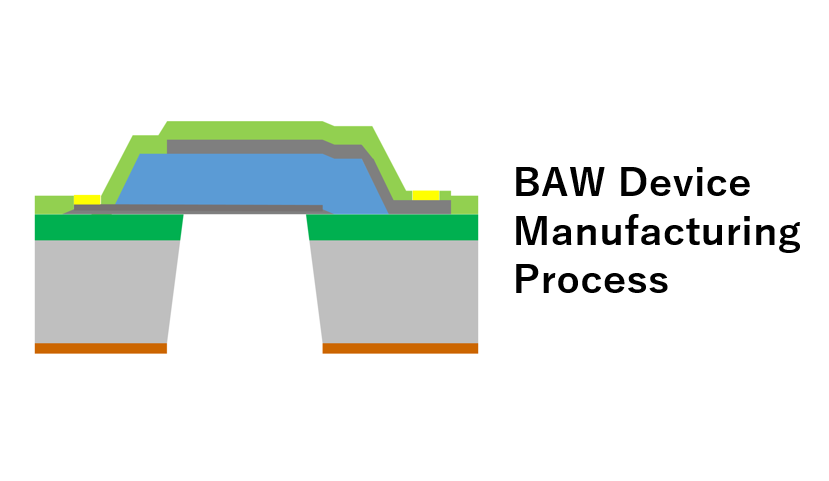

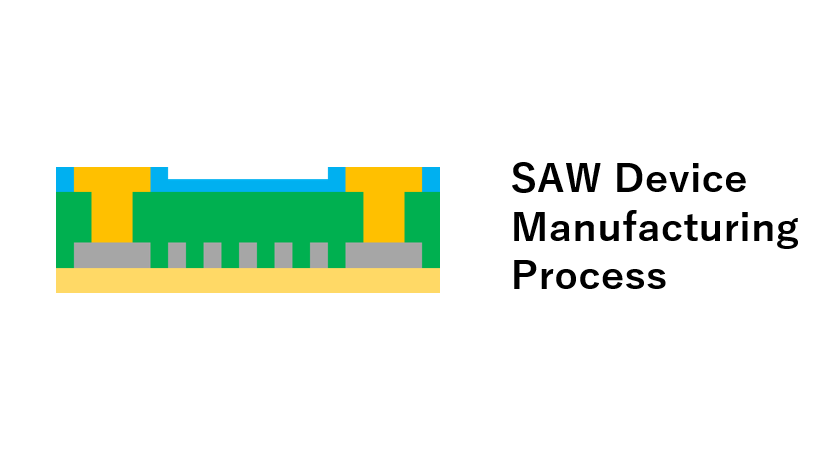

- MEMS sensor: PZT sputtering and etching

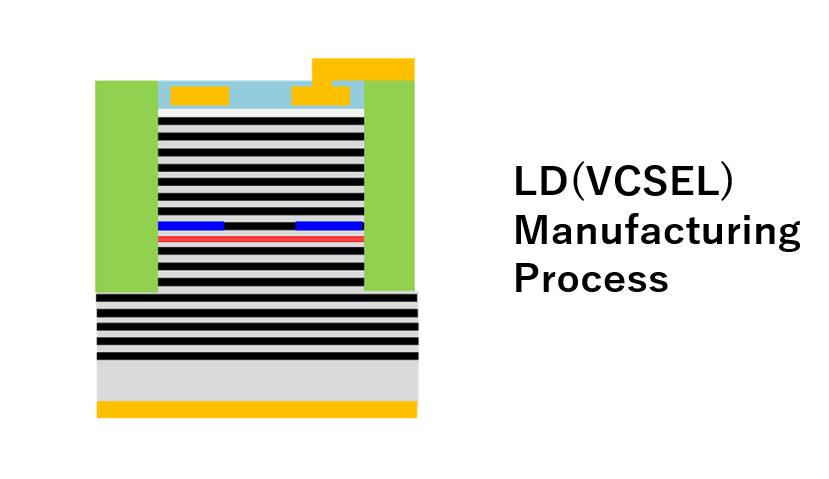

- Optical device: VCSEL etching

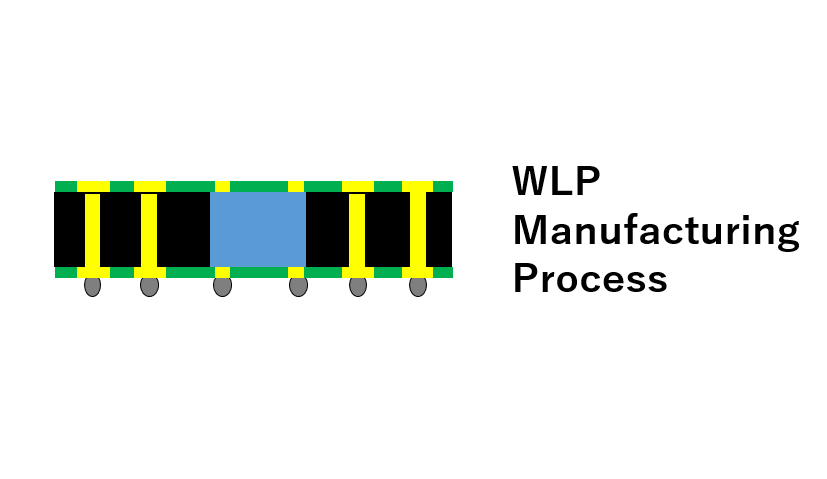

- Packaging: descum ashing

- Communication device: PE-CVD of insulated film and etching

Specification

Below are examples of available specs for each process chamber.

The specs are customizable and may vary for each case. Please inquire for detail.

| Ultimate pressure |

Stage temperature |

WIW uniformity (reference values) |

Usage and applications | Plasma source | |

|

Sputtering |

<6.7E-5Pa |

Cold |

±1~5% | Metal, dielectric film, insulated film |

DC |

| Pulse DC | |||||

| RF | |||||

|

Etching |

<1.0E-3Pa | -20 to 200℃ | <±5% | Metal, dielectric film, insulated film, Si based films |

CCP |

|

ISM |

|||||

| NLD (Neutral Loop Discharge、 ULVAC Patent) |

|||||

|

Ashing |

<0.7Pa | 50 to 250℃ | ±5% | Descum, desmear, sacrificial layer removal, surface treatment, PR removal and PI etch |

Microwave |

| 20 to 80℃ | Microwave+CCP | ||||

| PE-CVD | <2Pa | 60 to 400℃ | <±1% | Insulated film(SiNx,SiOx) | Anode coupling |

| Dual Frequency |

System configurations

Various modules can be equipped. Examples below.

*Certain combinations may be unavailable depending on the process, so please consult with us.