This post is also available in:

Japanese Chinese (Simplified)

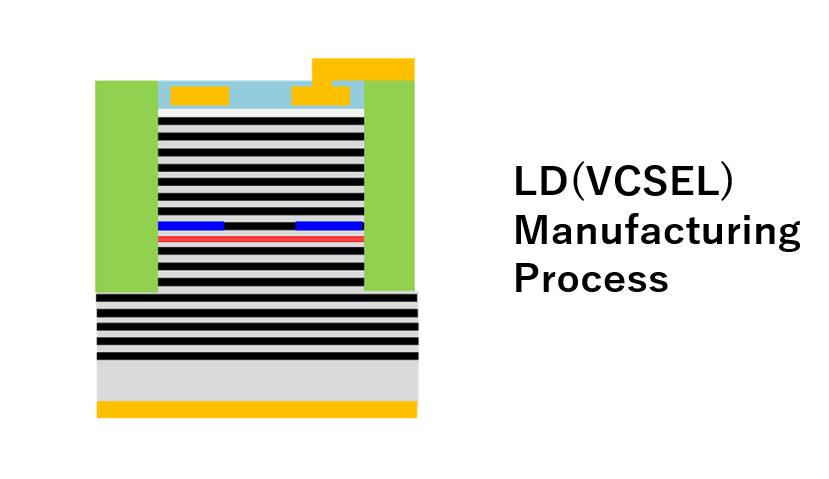

The market for semiconductor lasers is becoming active as a light source for 3D sensing technologies such as LiDAR, which are required for autonomous driving. As one of them, we will introduce a dry process for VCSELs (Vertical Cavity Surface Emitting Laser), which has merits such as miniaturization and energy saving.

VCSEL fabrication flow

|

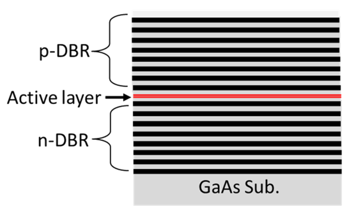

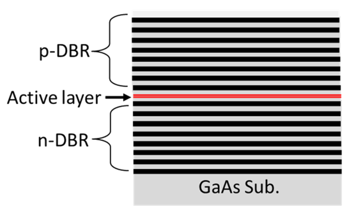

1. Epi growth

On a GaAs (gallium arsenide) substrate, AlGaAs / GaAs layers are epigrown as a laminated structure including a DBR (Distributed Bragg Reflector) multilayer film consisting of several tens of pairs or more and an active layer. |

|

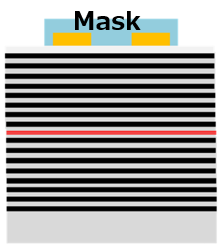

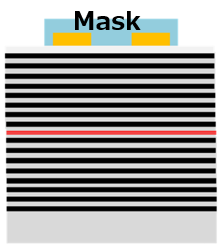

2. Patterning & Mask forming

Form a mask pattern to form the epi layer into a column called a mesa |

|

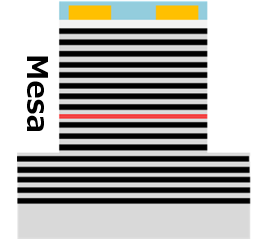

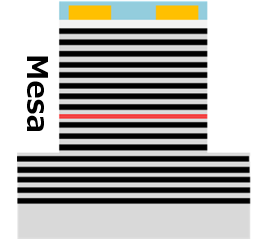

3. Patterning Mesa

Patterning Mesa by dry etching

Process technology for VCSEL

Introduction of Etching module |

|

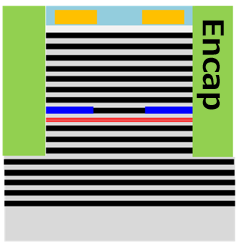

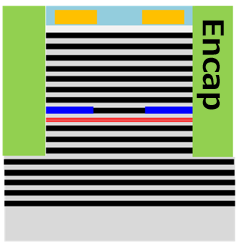

4. Forming active layer & encapsulation

A specific AlGaAs layer designed near the active layer is oxidatively narrowed by wet oxidation (this oxidative narrowing layer is a very important layer that influences the characteristics of the VCSEL as a current and light confinement structure). It also forms a protective film on the side wall of the mesa. |

|

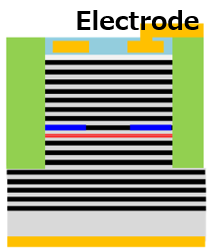

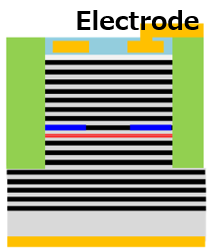

5. Forming electrode

Electrodes are formed on each of the n-type and p-type layers. |

Contact Us