This post is also available in: Japanese Chinese (Simplified)

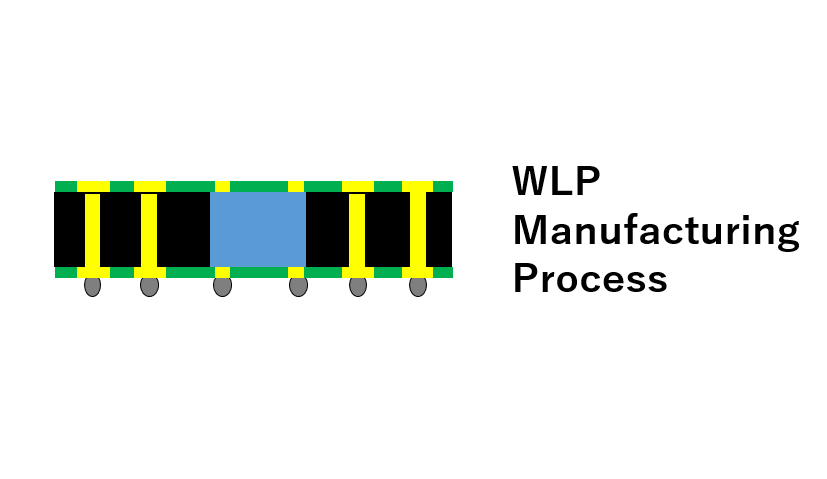

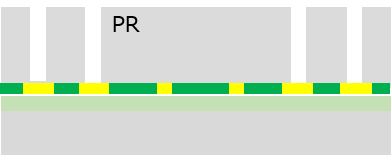

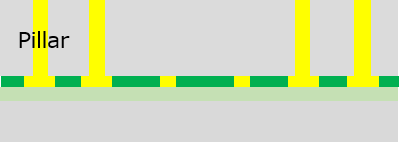

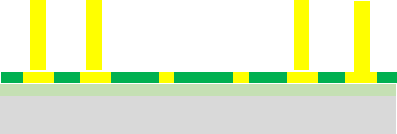

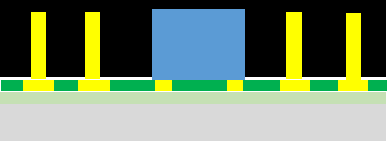

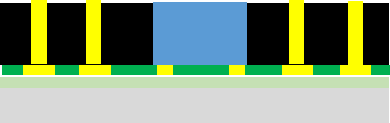

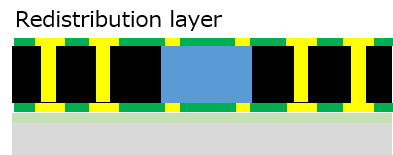

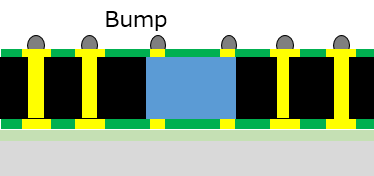

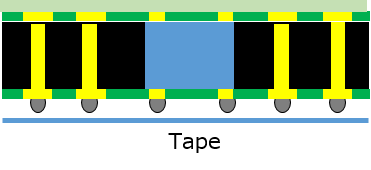

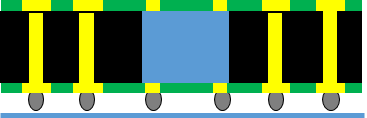

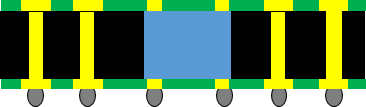

WLP is an abbreviation for Wafer-level Packaging, which is one of the mounting technologies expected as mobile devices such as smartphones become more sophisticated and thinner. ULVAC provides techniques such as sputtering, etching and ashing for the WLP manufacturing process.