This post is also available in: Japanese Chinese (Simplified)

GaN HEMT (High Electron Mobility Transistor) is a next-generation power semiconductor that has low operating resistance and high breakdown withstand voltage, and is expected to be applied to high-power and high-speed electronic devices.

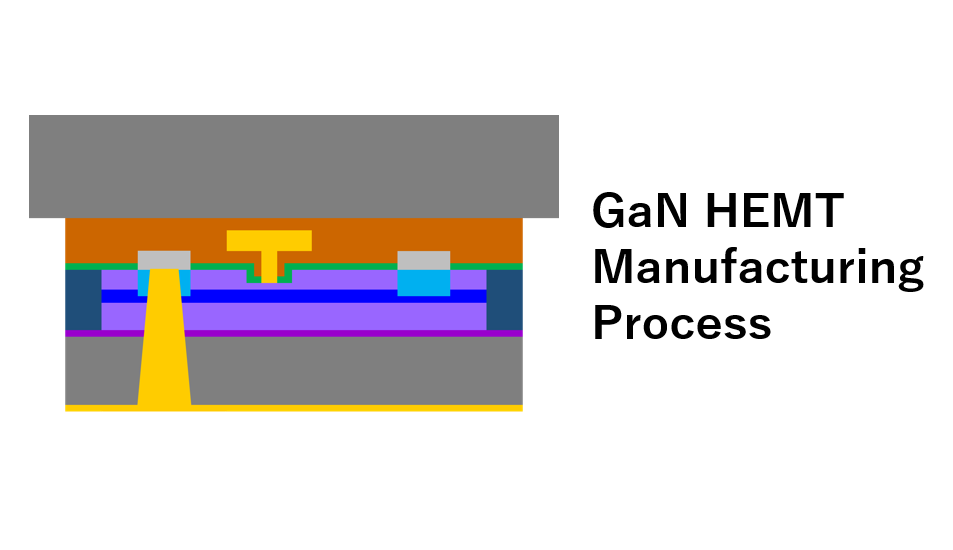

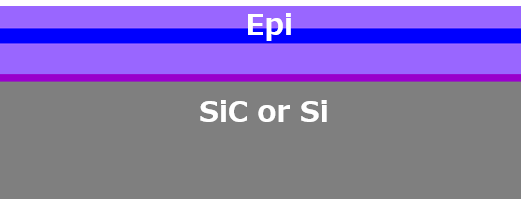

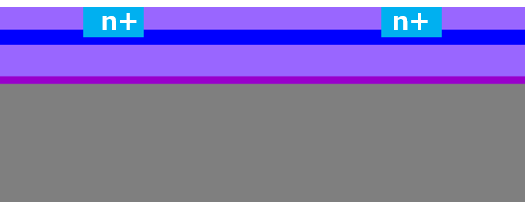

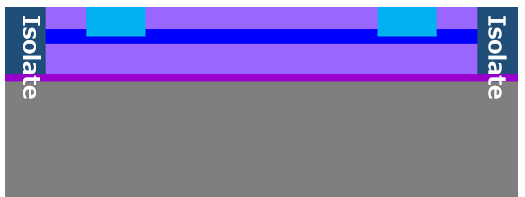

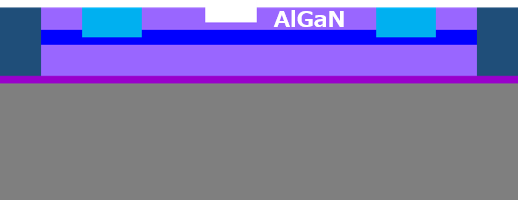

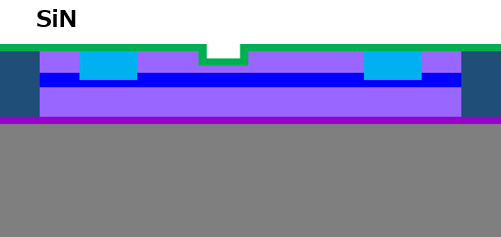

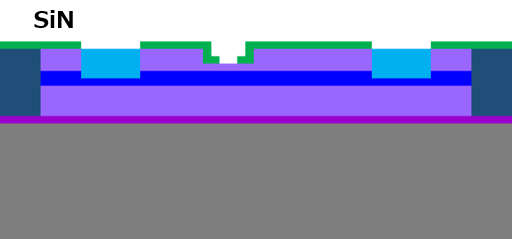

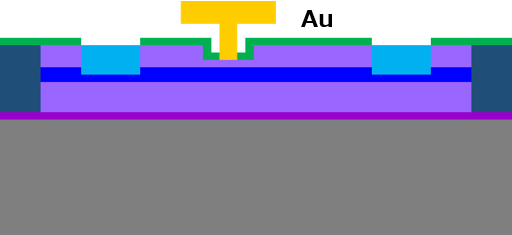

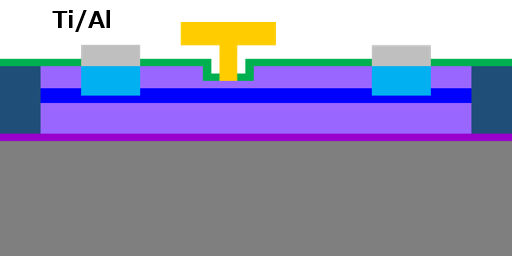

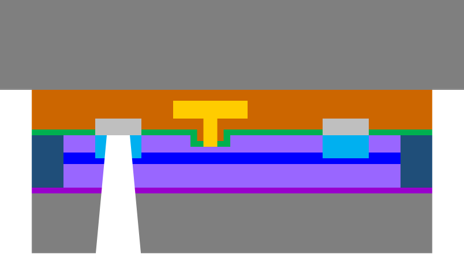

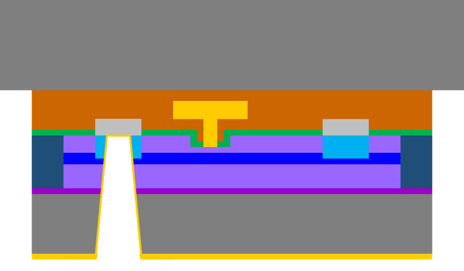

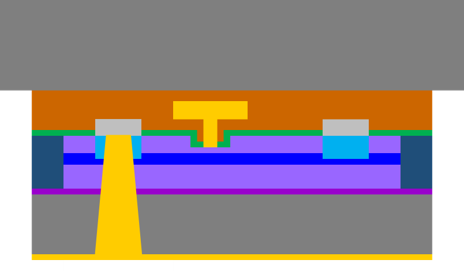

GAN HEMT Fabrication flow