Dry Etching System

Model:uGmni-200E

A versatile etching system that supports both single-chamber and multi-chamber configurations, offering cost performance and scalability for production scale.

Features

- Equipped with a "star electrode" to prevent deposition on the RF input window.

- Heating function enhances reproducibility and stability.

- Uniformity control is possible by adjusting the RF distribution ratio to a dedicated inner and outer perimeter separated antenna with ISM-duo (optional).

- A process chamber capable of handling gas flow rates up to twice that of our standard models (optional).

High-temperature heating for the process chamber is selectable (optional). - Additional etching chambers and ashing chambers can be equipped.

- The ashing chamber offers microwave water plasma treatment on a heated stage to prevent corrosion after metal etching.

- The system’s simple structure ensures easy maintenance.

- A dummy cassette and alignment mechanism can be added, enabling the system to support a variety of processes as a production tool.

- Comprehensive support services, including cleaning, parts supply, maintenance, and training, are provided.

Applications

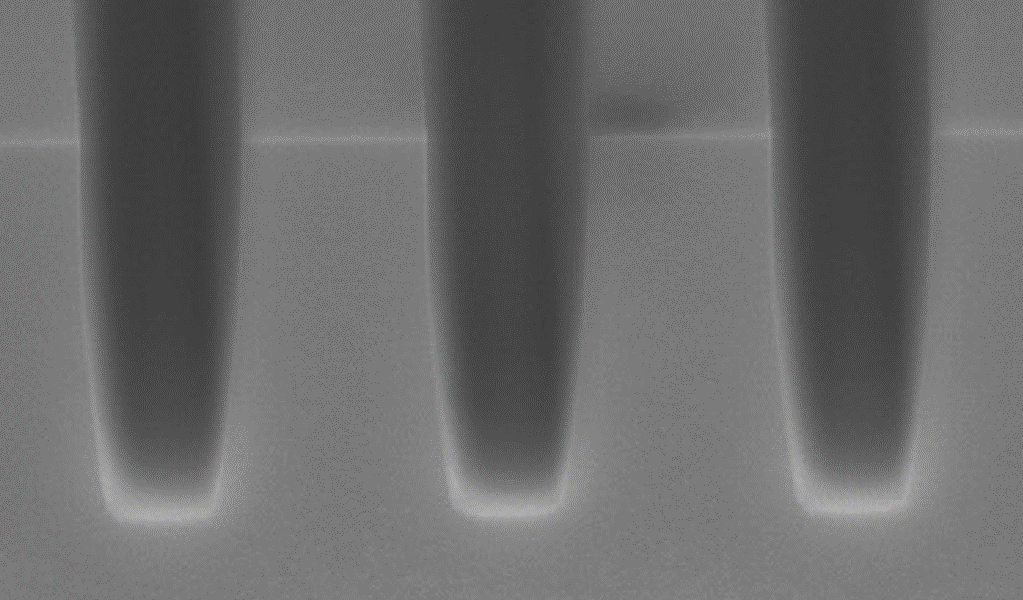

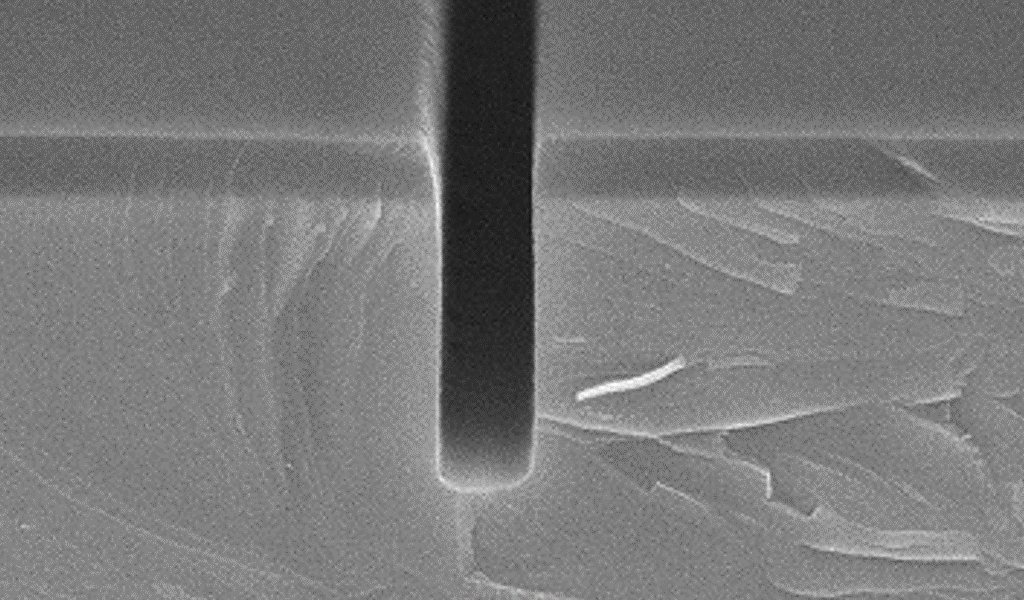

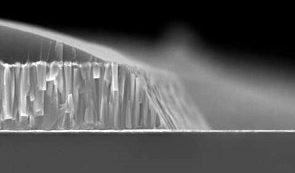

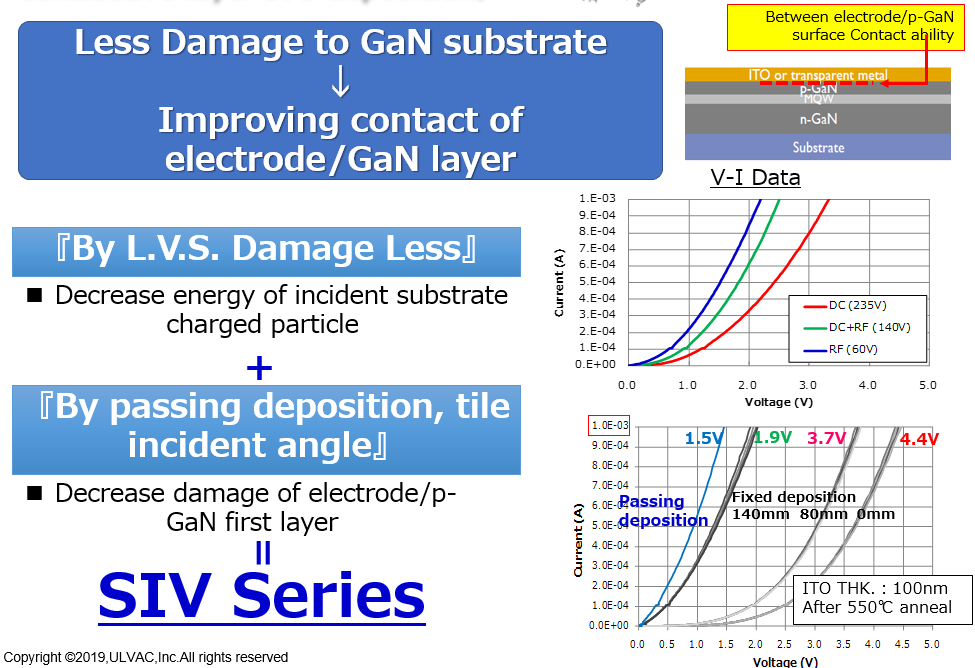

- Compound semiconductors (LED, LD, VCSEL RF devices and communication devices), Power devices (IGBT, SiC)

- Metal, Dielectric, Polymer, Gate electrode etching

- Ferro electric material, Noble metal etching

- Ferro magnetic material etching