This post is also available in: Japanese Chinese (Simplified)

We provide dry etching technology to realize a trench structure that realizes miniaturization and low resistance of power devices.

Challenges

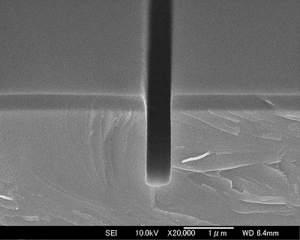

Control Trench shape

The bottom is rounded to prevent device destruction due to concentration of electrolysis on the corners of the bottom.

Damage to sidewalls

Damage to the surface affects device performance

Solutions

Realization of smooth side walls and round shape

Optimize etching conditions to control trench shape

Removing damage layer

The damaged layer formed by trench formation is removed by ultra-low speed etching and low temperature annealing.

|

|