Dry Etching System

Model: NE-550EX

high-density plasma etching system featuring an Inductively Coupled Plasma (ICP) method with a static magnetic field (ISM). It adopts a single-wafer structure and comes standard with an LL chamber. This model offers a compact design and low cost, making it an ideal choice for research and development.

Features

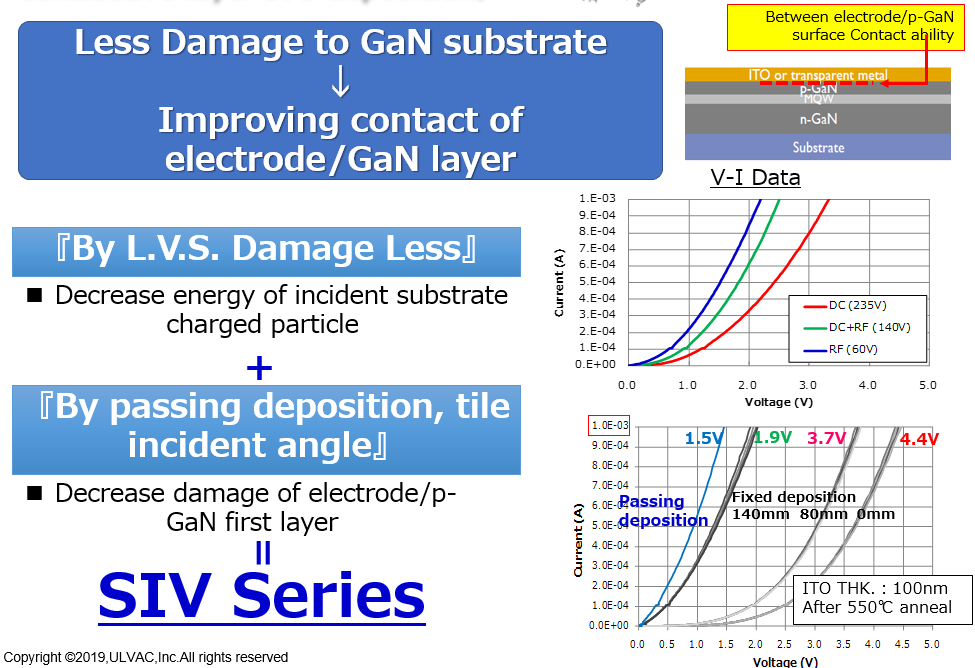

- Magnetic field assistance enables the generation of low pressure, low electron temperature, and high-density plasma, allowing for a wide range of plasma control, from ion-based etching to radical-based etching, compared to other ICP methods.

- The RF input window features a "star electrode" to prevent deposition, along with a heating function, focusing on reproducibility and stability in the system design.

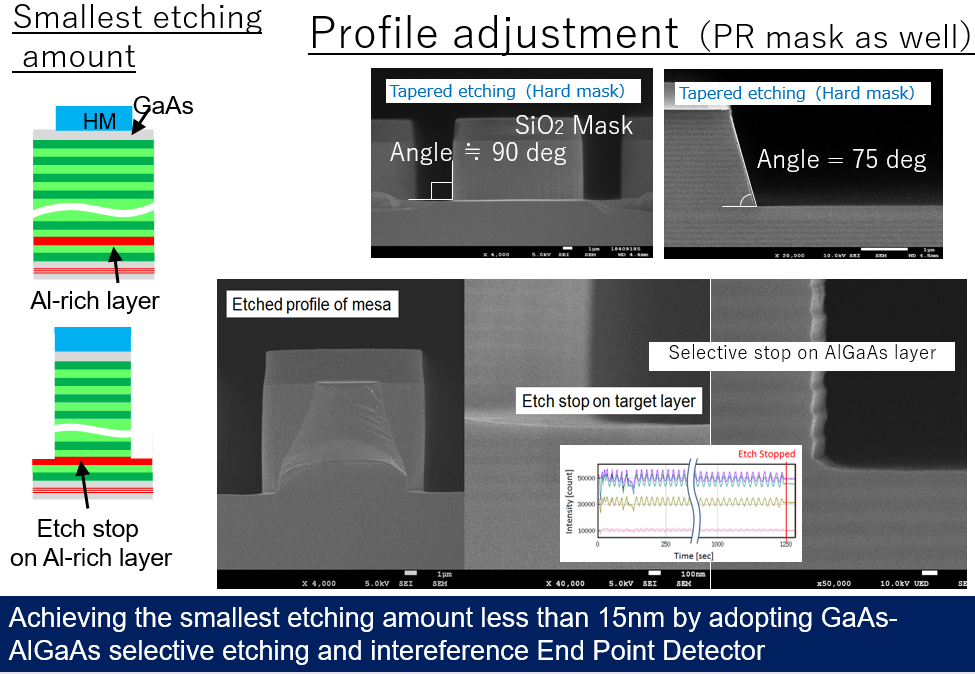

- The system’s simple structure ensures easy maintenance. Additionally, a variety of options are available, including a cassette chamber, 200°C substrate heating ESC stage, and endpoint detection mechanism.

- The system uses the same chamber as the uGmni-200E, designed for production scale lines, offering flexibility to support diverse processes as a development tool.

Applications

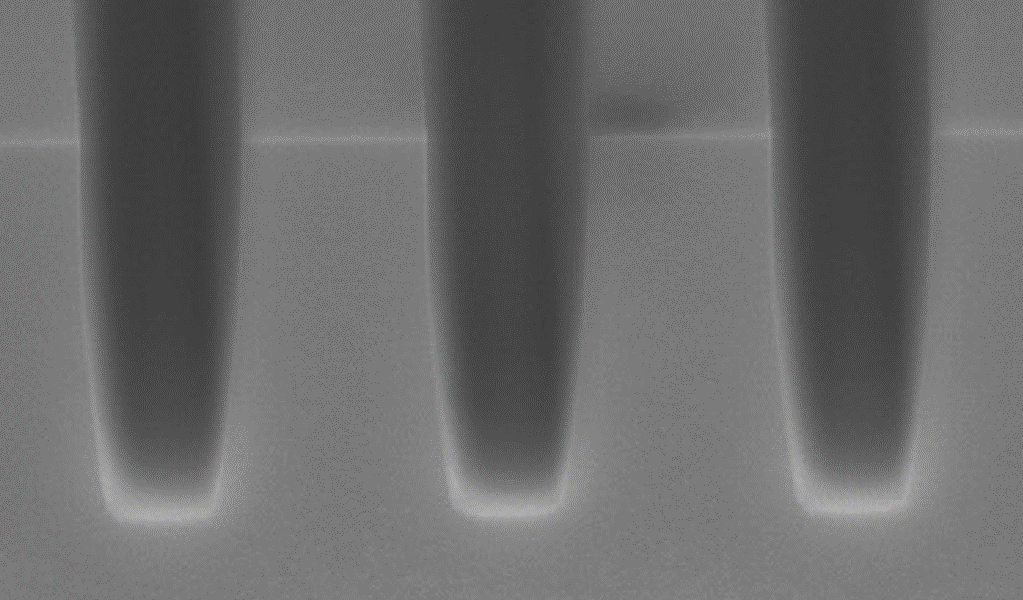

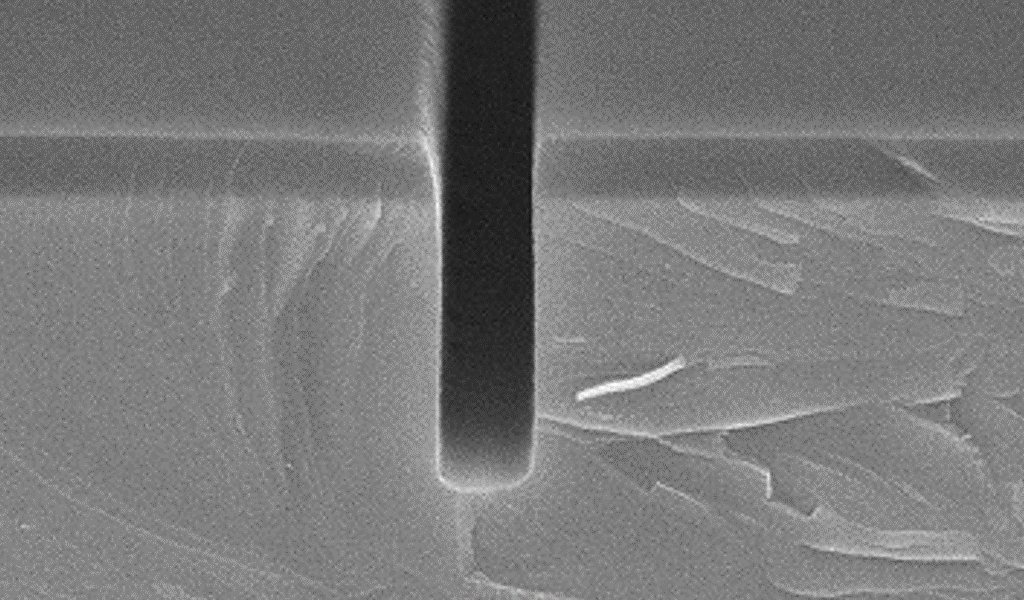

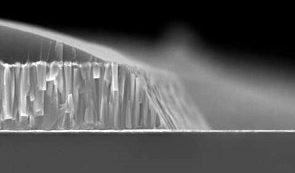

- Compound materials (LED, LD, VCSEL, high frequency devices, communication devices and power devices).

- Metal, Dielectric, Polymer, Gate electrode etching

- Difficult-to-etch materials(ferroelectrics, precious metals, and magnetic films)

- Nanoimprint, NEMS, MEMS, various sensors.

- Biochips, microfluidic devices, photonic crystals, etc.

Specifications

| Model | NE-550EX |

| Wafer loading | Single-wafer loading or cassette |

| Wafer size(mm) | ~ Φ200 mm |

| Operating pressure (Pa) | 0.07 to 6.7 |

| Uniformity within wafer/wafer to wafer | ±5% max. |

| Wafer chucking | Mechanical chuck or electrostatic chuck |