Supply Chain

Suppliers are our important partners for manufacturing. We are working with them to enhance efficiency of the entire supply chain (from design, procurement, manufacturing, and sales, through to customer support), always being conscious of the environment and society.

-

Declaration of Partnership Building

In May 2024, ULVAC, Inc. has announced the "Declaration of Partnership Building" to build a new partnership through cooperation, coexistence and coprosperity with suppliers in the supply chain. The "Declaration of Partnership Building" is a mechanism established by the "Council on Promoting Partnership Building for Cultivating the Future", whose members include the Chairman of Nippon Keidanren, the President of the Japan Chamber of Commerce and Industry, the President of the Japanese Trade Union Confederation, and relevant ministers.

-

Communication with Suppliers

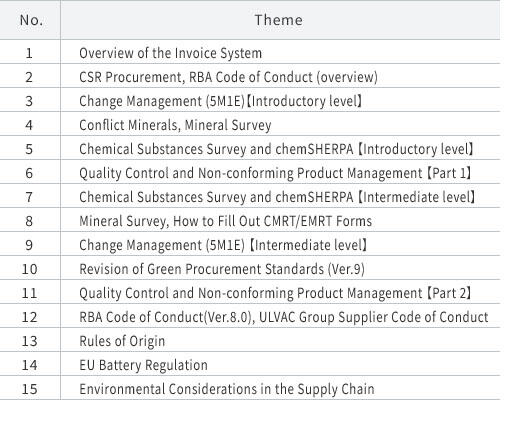

With a primary focus on strengthening relationships with suppliers and the supply chain, we held "individual seminars" on 15 themes for all suppliers in FY2023. The themes focus on those necessary for strengthening manufacturing capabilities, CSR procurement, and addressing social issues such as the environment, human rights, and ethics. The main themes are outlined in the table below.

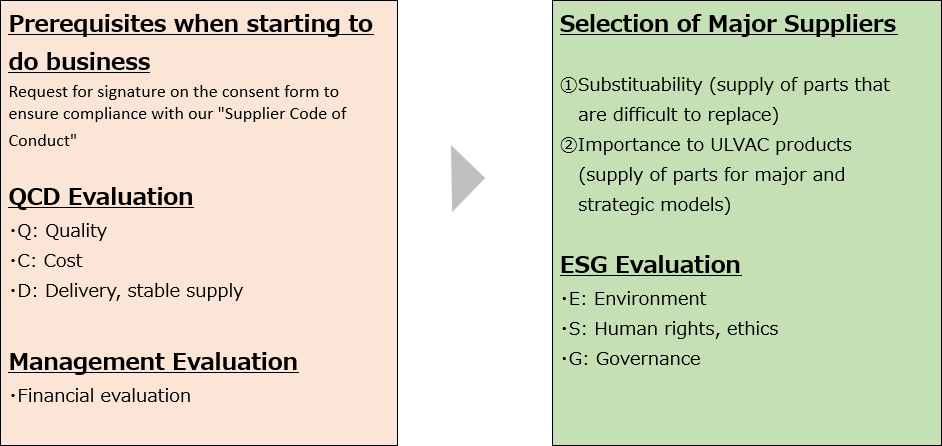

We hold an annual operations briefing meeting for our major suppliers, where the president and management directly explain the business environment and ULVAC's performance. Additionally, we host supplier meetings two to three times a year to timely communicate production plans from the person in charge of procurement to major suppliers. The major suppliers (approximately 250 companies) are selected based on the following criteria.

In FY2023, specific suppliers are invited to visit our company and hold "product exhibitions and briefing sessions" individually. In addition, utilizing the expertise of the Procurement Division's Processing Technology Office, we provided direct guidance to some of our suppliers by offering processing instructions and product drawings developed into individual part drawings. In this manner, we strive to build close relationships with our suppliers and we will continue hosting these events in the future.

Selection of major suppliers

At ULVAC, QCD evaluation and management evaluation are conditions for certification of all suppliers. In addition, the following conditions must also be met in the selection of major suppliers. In the results, our major suppliers account for approximately 80% of our total purchases in the previous fiscal year.

- ①Suppliers supplying parts that are difficult to replace

- ②Suppliers supplying parts for major and strategic models

- ③Suppliers who agree with stakeholder requirements in ESG initiatives

In addition, we will request our major suppliers to conduct CSR self-assessments in the future.

-

Themes for individual seminars

-

Product exhibitions and briefings

Global Production Bases

Taking advantage of their proximity to customers, ULVAC's principal production bases conduct local procurement and seek to optimize procurement as part of their ongoing efforts to establish a global supply chain.

Previously, when suppliers delivered parts for overseas production, all cargo was shipped via ULVAC's Chigasaki Plant.

With the introduction of a new transfer center, suppliers can now directly deliver parts to the center where all the processes from acceptance of delivery to export procedures are handled in an integrated manner, resulting in a great reduction of transportation distances in the supply chain and consequently lower energy consumption and lower exhaust gas emissions.

Integrated procurement system

ULVAC is improving procedures, systems and structures for procurement to realize global procurement at the parts level. Although we had been sourcing many key parts in Japan, we conducted benchmarking of suppliers worldwide and identified specific issues in logistics and trade. As it is necessary to ensure confidentiality, completeness, and availability of purchasing data on a system supporting global procurement, we have launched an integrated system for parts registration and for registration and evaluation of suppliers and begun standardization of management procedures.