Ashing System

Model: NA

The ashing system is available in two types: one designed for wafers and the other for panels.

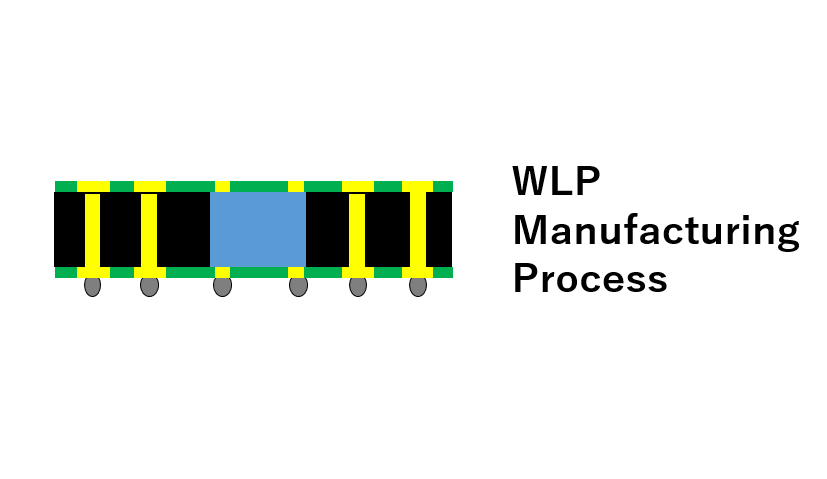

The wafer-compatible model features a wafer-size-free design, capable of handling a wide range of processes from next-generation wafer processes to wafer-level packaging. It is the most widely adopted device in semiconductor packaging processes.

The panel-compatible model supports panels up to 600mm square, allowing for uniform Descum processing and Ti etching even on large panels.

Features

Model: NA-8000 and 1300

- Enables damage-free ion implant stripping and polymer removal processes.

- The chamber configuration optimized for F-based gas addition processes allows particle-free operation. This makes it suitable for a wide range of processes, including normal PR, ion implant stripping, organic film stripping (PI, DFR, etc.), and oxide etching.

- Simple design ensuring excellent maintenance, reliability, and cost-efficiency.

- The option to choose from different chamber configurations (μ-wave, RIE, μ-wave + RIE) allows optimal settings based on the process.

- Easy wafer size change through recipe settings.

Model: NA-1500

- Selectable microwave downflow and/or RF bias.

- Suitable for Ti seed layer etching, Descum, and surface treatments.

- Supports new processes such as surface treatment and hydrophilization, in addition to ashing.

Applications

- High dose ion implant stripping process (10E + 16 atoms/cm2 or higher) and polymer removal in front end process

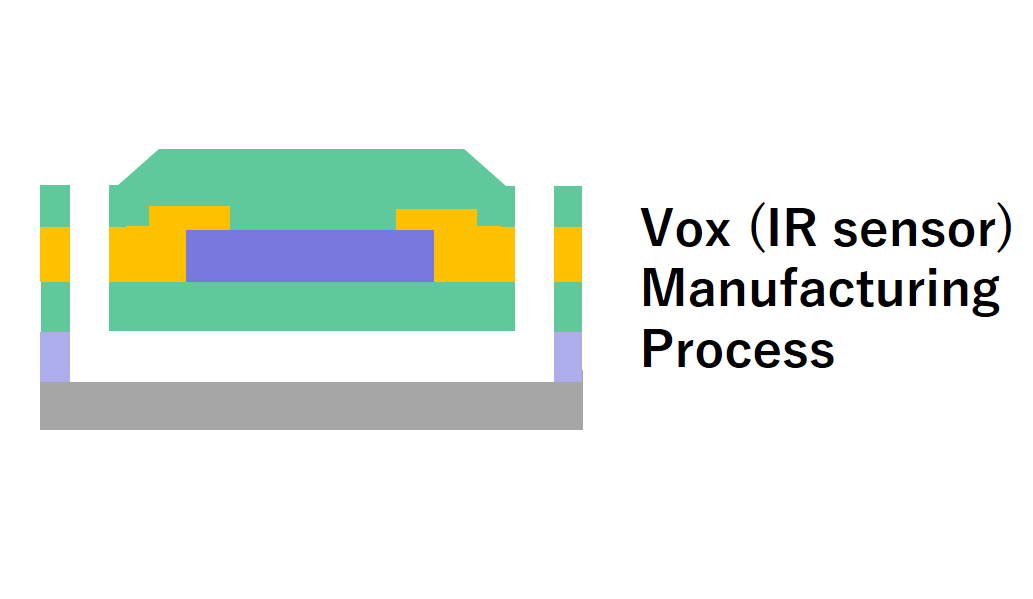

- Wafer process that requires CF4 addition process (electronic parts and LEDs)

- Chip size package and bump process

- CCD color filter manufacturing process

- Descum, Desmear

- Surface modification (hydrophobic to hydrophilic, hydrophilic to hydrophobic), pre-treatment for wet processes such as plating and underfill

- Ashing of resin-based materials

Specifications

| Model | NA-8000 | NA-1300 | NA-1500 |

| Wafer Size(mm) | Φ100~200 | Φ200 and Φ300 | Max. 600mm square |

| Process chamber | 1 | 2~6 | 2 |

| Plasma Source | MW、RF | MW、VHF、RF | |

| Applications | R&D~Small-scale production | Large-scale production | Panel level packaging(PLP) |