This post is also available in: Japanese Chinese (Simplified)

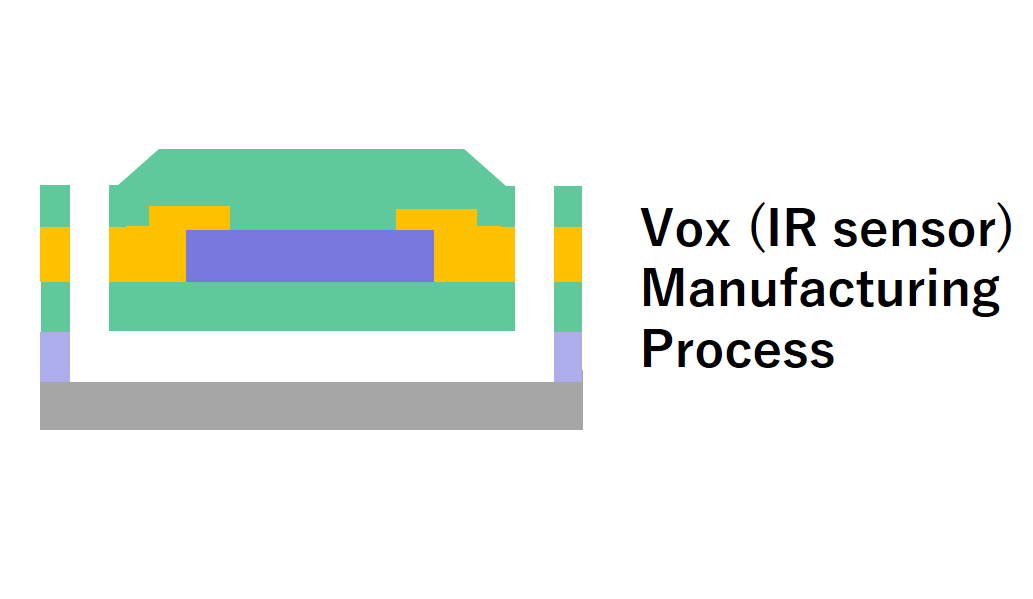

Infra-red sensor (IR-) is an important sensor for realizing visualization in the dark night, and it can detect the heat of the object, so it can visualize obstacles (animals with a heat source, etc.) even in the dark night.

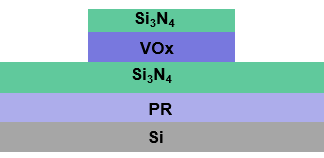

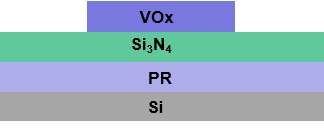

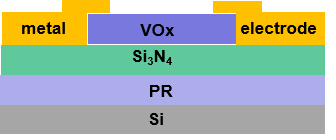

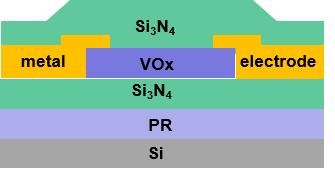

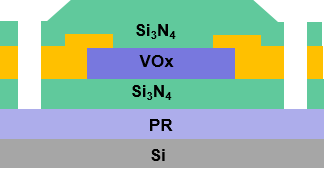

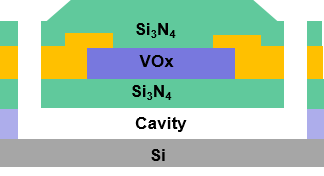

There is a technology that uses conventional amorphous silicon (Amorphous Silicon, a-Si), but in recent years, a new material, vanadium oxide (VOx), has been attracting attention in order to achieve higher performance. .. Since the resistance of VOx changes due to heat, the resistance change is large, and the linearity is high, it is expected that noise can be reduced compared to the conventional infrared sensor using amorphous silicon.