This post is also available in: Japanese Chinese (Simplified)

Introducing the piezoelectric film processing technology required for SAW device production and ULVAC technology used for electrode formation.

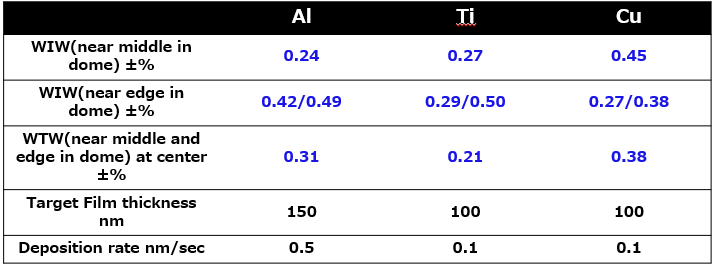

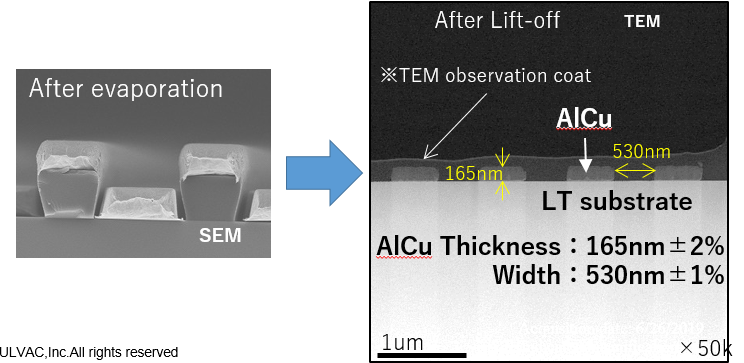

IDT electrode deposition(Evaporation)

SAW dedicated machine specializing in high-density uniformity

Liftoff process

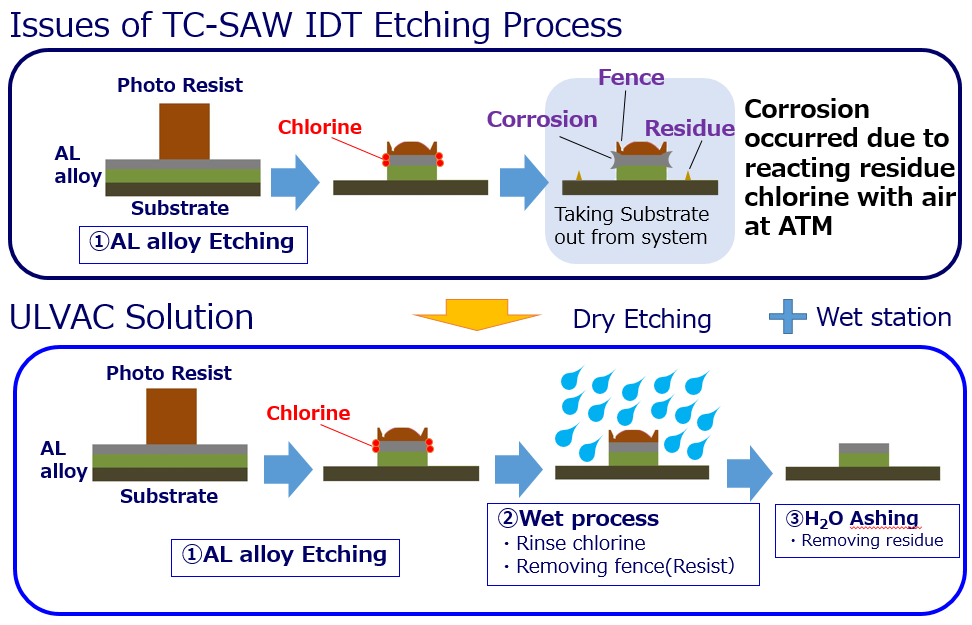

IDT electrode etching

One of the issues in the dry etching method is the occurrence of after-corrosion. If Al-based materials are not post-treated immediately after dry etching, corrosion will occur due to the reaction between moisture in the atmosphere and residual chlorine components, so it is necessary to remove residual chlorine before opening to the atmosphere.

In addition, fences such as horns and residues may be confirmed in this way, so it is best to remove them together. Especially in AlCu alloys, corrosion is remarkable when the Cu content is high.

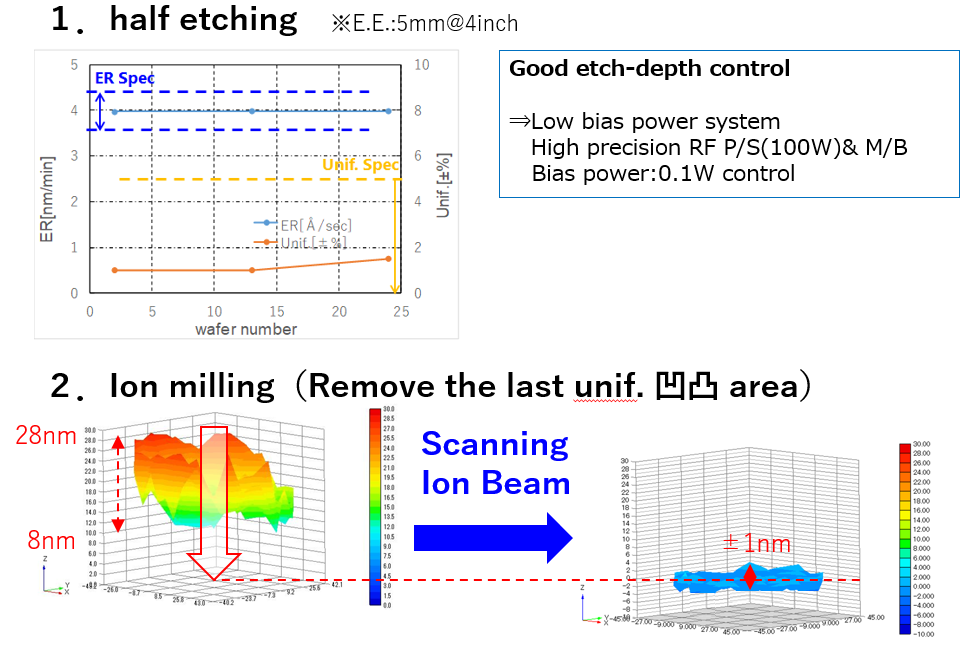

TC layer Half Etching + Trimming

After forming a film with SiO2, Half signaling + Ion milling is performed. The LN / LT substrate is deformed by thermal stress. Since the LN / LT substrate is deformed by piezoelectricity and carries radio waves, if it is deformed by heat, it will not function as a filter in places where there is a large temperature difference. By adding SiO2, the reverse thermal stress is applied and offset by the LN / LT stress. This SiO2 distribution is so important that a good distribution is required.