Customer Support

Field Services for Equipment

We offer an initial set-up and operation, field service, CIP (Continuous Improvement Program), material recycling.

Field Service

1. On-Site Service Engineers

Technicians are on duty to inspect whether the product line is properly functioning, and to replace parts such as inner jigs and evaporation sources.

2. A wealth of Experience and Expertise

Our service ranges from preventive maintenance, overhaul, repairs, remodeling, relocation, disposal to overall maintenance.

Global CIP

ULVAC promotes a unique and innovative plan called CIP(Continuous Improvement Program) whose services include the upgrading of existing equipment.

To increase the yield rate and improve productivity, it is essential to utilize existing line equipment for generations to come. This plan is not for only equipment used in Japan, but also for those used overseas.

1. Meeting Demands of Next Generation Process

By adding and renewing hardware and software to the latest version you can get the benefits of the newest your current equipment at an affordable price.

2. Improving Productivity, Yield Rate, Process Capability, and Operating Rate

By adding the latest technology elements or renewing certain functions or units, yield and operation rate of your equipment will improve. Furthermore, we will help you raise productivity of existing line equipment by setting the system up or narrowing it down to functions to fit your needs.

3. Upgrading and Retrofitting

Upgrading existing equipment by adding new functions will make your system meet newest technology standards, and improve its control software.

4. Contribution and Dedication to Environment-friendly

By renewing certain products, or by switching just the hardware and software, you can change your existing equipment to more energy-saving devices.

We also suggest renewal of your equipment units and parts to meet RoHS regulations.

Factory Outsourcing (FOS)

A service for supporting factory operations to achieve manufacturing and developmental goals.

We suggest unique plans that meet your demands.

1. Man power at the initial start-up of production line

2. On-site services that require technical knowledge or skills (e.g. initial start-up of machine)

3. Line operators

4. Machine upkeep and maintenance

5. Comprehensive management of pump overhauls

6. Selection of model types and support for process development

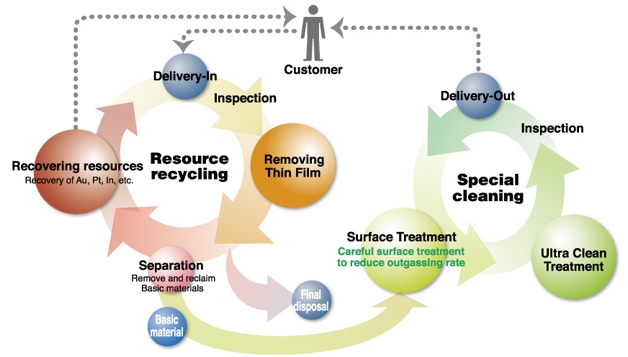

Recycling/Cleaning/Reusing Resources

Meeting Demands for Large-size Parts

From regular cleaning, blast cleaning to assembling, we meet demands for large-size equipment

-

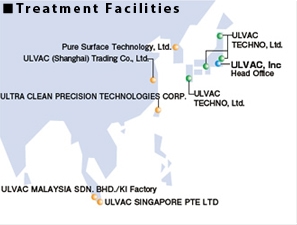

Treatment Facilities

ULVAC has many treatment facilities in Asia that has many device company.

Please inquire a nearby service center. -

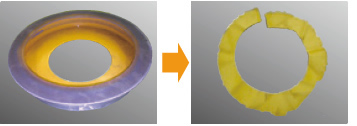

Case1: Ultra Clean Treatment

- ・Low outgas/ low dust

- ・The Anchor effects enable lengthening intervals of cleaning and longevity of parts due to decreased amount of deposition film peel off

- ・ULVAC's original spray coating technique

- ・A perfect solution to satisfy your need

-

Shield ring (1)

-

Platten ring

-

Shield ring (2)

Case2: Cleaning for Organic EL (Clean Harmless Treatment)

ULVAC has developed a cleaning method for organic EL device process called "Clean Harmless Treatment".

This new cleaning technology will support customer's requirements.

-

Reusing Resources (Au)

-

-cleaner and longevity of parts

-recyclable deposited film

-less damages to the environment

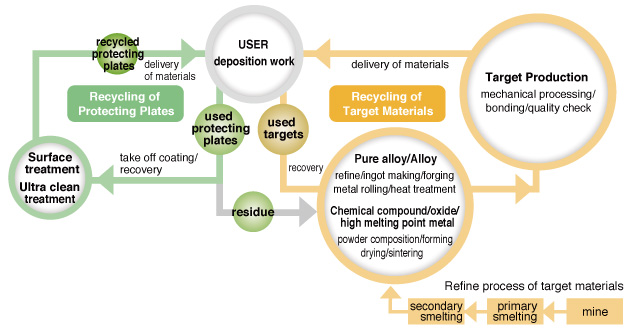

Case3: Recycling for Sputtering Targets

At ULVAC, resource recovery, recycling and reuse of valuable rare metals are implemented in a proactive manner to pursue efficient use of sputtering targets.

Parts Supply

We offer High quality, low cost, prompt and steady delivery of vacuum consumable parts and materials to users all over the world.

Various consumables for thin film deposition system

-

Silicon Parts (Electrode Outer)

-

Quartz Parts (Ring Shield)

-

Susceptor

-

Backing Plate

-

Shield

Parts for Vacuum Gauge/Thickness controllers

-

Vacuum Gauge Heads/

Various Vacuum Introduction Terminals -

Thickness Controller Parts

Vacuum Parts Supplies and Accessories, etc.

-

Bellow

-

Bellow

-

Oil for Rotary Vacuum Pumps

-

Oil for Rotary Vacuum Pumps Grease Specifically Made for Vacuum Equipment

-

Oil Mist Trap

-

Maintenance Parts for Vacuum Pumps

-

Part Supplies and Ac

-

Oil Mist Traps for Small-size Vacuum Pumpss

Surface Treatment

We offer surface treatments for high performance demands including vacuum equipment parts.

※ Scroll through the Table

| Surface Treatment | Treated Materials | Features |

| VACAL-SAL VACAL-OX |

aluminum, aluminum alloys |

An anodized film with lower crack ratio developed for etching and CVD equipment. |

| TUFRAM | aluminum, aluminum alloys |

A proprietary polymers impregnated surface to improve wear resistance, self-lubricity and non-stick release properties. |

| NEDOX NIFGRIP |

stainless steel, iron and copper alloys |

A proprietary polymeric impregnation to improve wear resistance,self-lubricity and non-stick release properties. |

| LECTROFLUOR | iron, stainless steel, aluminum alloys, glass, etc. |

A poly-fluoro film applied by electrostatic spraying to improve wear resistance, self-lubricity and non-stick release properties. |

| TIGOLD(TiN) CROMIT(CrN)/ DLC |

metal, stainless steel, aluminum alloy, ceramics and heatresistant plastic |

Fixture tool, mold, consume frictionresistant, anticorrosion, increase tribology and good for environment surface treatment. |

| Optical Coating by Sputtering. | PET films, plastic, glass |

Optical coatings and design to anti-reflection on plastic sheets/films and glass plates. |

Analysis Service

ULVAC conducts paid analysis work on request using the measurement systems we manufacture and sell.

We provide useful data for materials development and quality management.

-

Differential Thermal Analyzer TGD-9600

-

Laser Flash Type Themal Constant Analyzer TC-9000

-

Seebeck Coefficient and Eletric Resistance Measurering System ZEM-3

※ Scroll through the Table

| Analytical Testing Purpose | Measurement Sample | Corresponding System |

| Thermal analysis | Metallic materials melting/solidification Sintering Thermal resistance |

TGD-9600 Thermogravimetry/Differenctial Thermal Analyzer |

| Heat expansion | Quartz, Low expansion glass Polymer film |

LIX-2 Thermal Expansion Equipment by Laser Interferometer |

| High temperature observation |

Various metals | TMS-E1S High Temperature Observation System |

| Thermal conductivity |

Polymer films Polymers, Ceramic substrates |

FTC-1 Periodical Heating Method Thermal Diffusivity Measuring System |

| Metal Ceramics Polymer films Polymers, Ceramic substrates Heat dissipating sheets Thermoelectric conversion materials Carbon, Graphite |

TC-9000 Laser Flash Method Thermal Constant Measuring System | |

| Seebeck coefficient | Thermoelectric conversion materials | ZEM-3 Seebeck Coefficient/Electric Resistance Measuring System |

| Saturated vapor pressure measurements |

Organic dye (EL materials) Oils, Fats |

VPE-9000 Vapor Pressure Evaluation System |

| Relative change in viscosity | Liquid, Oil | RSM-1 Resonance Shear Measurement System |

In addition,various analysis is possible.

Used Equipment/Refurbish

ULVAC offers various types of used items, ranging from single parts to production systems. ULVAC also assists our customers in the collection of information in the used machinery market. With technical staff specialized in trading, modifying, relocating, exporting, and importing used items, ULVAC offers a unique approach to respond to its customer needs.

ULVAC, based on its experience as a machinery manufacturer, offers product support and distribution services.

Features

ULVAC's expertise as a vacuum system manufacturer offers value-added services that our competitors cannot match, with its expertise. ULVAC offers its customers cutting-edge technologies as used in the latest vacuum systems as added value.

Services

- ・Distribution of equipment

- ・Purchase of machinery

- ・Relocation and export/import of machinery

- ・Modification of machinery (remodeling/retrofit)

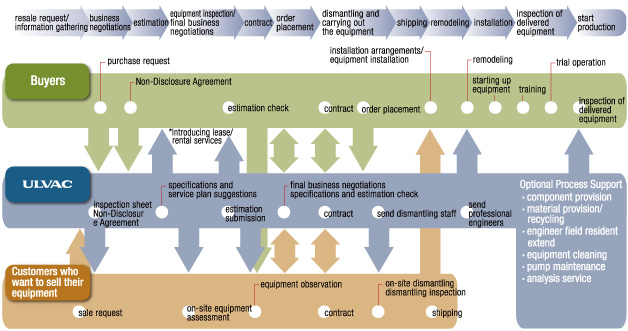

Business Flow