Occupational Safety and Health

The ULVAC Group has made "Safety First" the fundamental principle of business management. By operating our Occupational Safety and Health Management System (OSHMS) focused on risk assessment, we endeavor to ensure safety of the products and services used by our customers and create dynamic workplaces where Group employees can work in good physical and mental health.

Approach on Occupational Safety and Health

In the execution of development, manufacturing, transport, installation, maintenance and other business processes, everyone in the ULVAC Group, from senior management to line workers, is encouraged to seize the initiative in continuously undertaking improvements placing the highest priority on safety, striving to maintain and improve the safety of everyone involved and ensure a healthy working environment. Under the "ULVAC Basic Policy on Occupational Safety and Health Management System (OSHMS)," all executives and employees work together to promote continuous improvement activities to provide a safe and comfortable work environment. Each ULVAC Group company also complies with the safety and health laws and regulations of each country and region, aiming for "zero occupational accidents" and working to reduce risks.

ULVAC Basic Policy on Occupational Safety and Health Management System (OSHMS)

1. Compliance to the code/regulations, and implementation of risk assessment

Comply with Codes of Occupational Safety & Health Management and Rules according to ULVAC's OSHMS, and conduct Risk Assessment in order to perform Occupational Safety & Health Management activities with the help of all the employees.

2. Assure safety of ULVAC's products

Comply with ULVAC's standard for safety design and perform risk assessment of our products, in order to deliver our safe products and services to our customers.

3. Planned education about Occupational Safety & Health & Product Safety

For all the employees and contractor's employees, perform Occupational Safety & Health training based on ULVAC Safety Management system, while offering scheduled Product Safety training for our users.

4. Promotion of mental health care

Promote mental health care achieve a health, vigorous workplace environment.

5. Global expansion of ULVAC group

Through the Safety & Health promotion activities by the Global Safety Committee, We will strive to create a safe, secure and appropriate working environment for the whole ULVAC group, and contribute to prosperity of our businesses.

Risk and Hazard Assessment

Identify potential hazards in the workplace and evaluate them through risk assessments. Implement processes to identify risks during work planning and take risk reduction measures before starting work.

Action Plans and Quantitative Goals

Develop action plans to address identified risks and set measurable goals based on the company's annual safety and health targets. This clarifies progress toward risk reduction and prevention of occupational accidents.

Emergency Preparedness and Response

Develop emergency response plans and organize emergency evacuation drills and emergency communication systems. This ensures rapid and appropriate response in the event of an emergency.

Progress Evaluation

Regularly evaluate progress against established safety and health goals and ensure continuous improvement and goal achievement through reports at safety management promotion meetings.

Regular Internal Audits

Conduct internal audits based on the annual audit plan by designated internal auditors to verify compliance with laws and the effectiveness of the safety management system.

Accident Investigation Procedures

In the event of work-related injuries, health disorders, illnesses, or accidents, issue corrective recommendations as non-conformities and implement cause investigations and recurrence prevention measures.

Training

Provide safety and health training, including risk assessment implementation education, to employees and relevant parties, aiming to raise safety awareness and eliminate operational accidents.

Implementation of Safety and Health activities

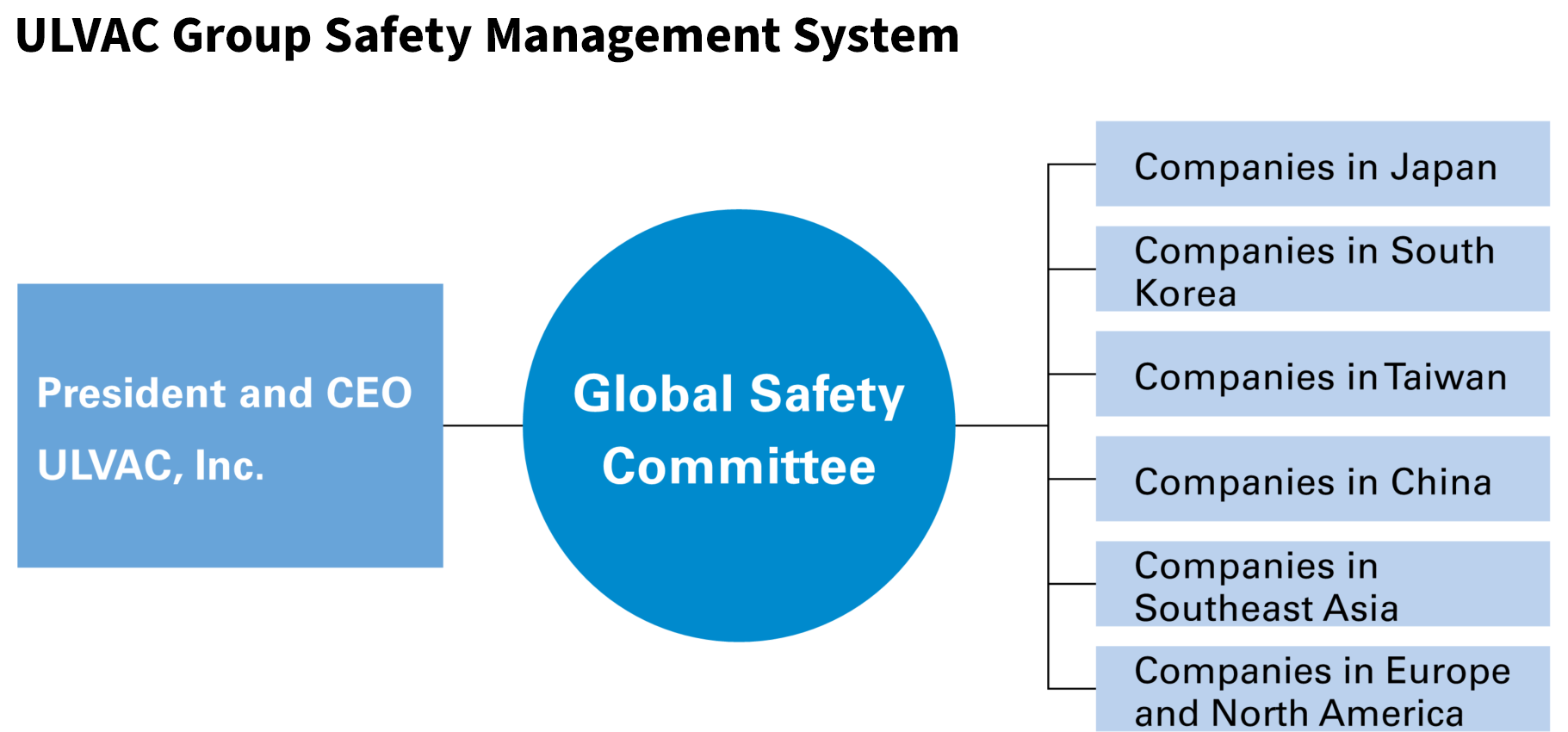

To ensure the safety and good health of its customers and employees, the ULVAC Group holds meetings of the Global Safety Committee, twice a year and all Group companies promote safety and health activities in an integrated manner. Furthermore, we have established a network of the safety personnel in each Group company and promptly share, discuss or implement safety information such as revisions of laws and effective accident prevention measures.

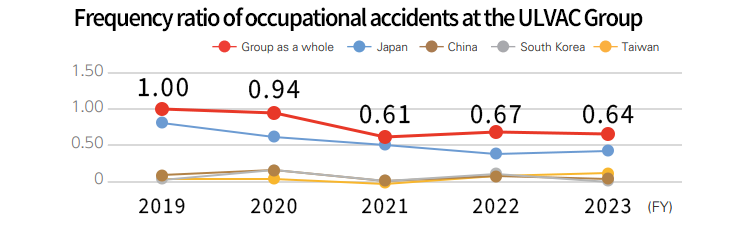

Each Group company operates the OSHMS and declares safety based on management reviews conducted by the president and other executives. To ensure safety, every employee is engaged in occupational safety and health activities through risk assessments etc. We identify hazardous risks at the time of work planning and implement measures before commencement of work. The positive impact of the strengthening of safety measures is apparent in the trend of the frequency ratio of occupational accidents.

We hold monthly meetings of the Safety and Health Committee at each business site, where representatives from the company and the labor union work together to discuss workplace safety and health of employees.We also hold Safety and Health Council meetings twice a year to share a variety of information on safety and health activities in an effort to prevent accidents in unison with our contractors.

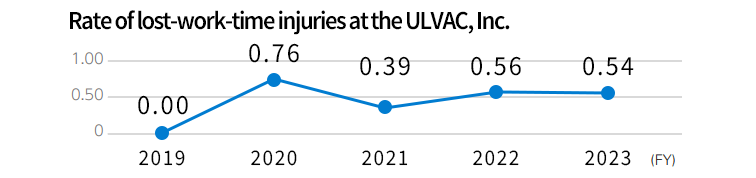

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | |

| ULVAC, Inc. on a non-consolidated basis |

0.00 | 0.76 | 0.39 | 0.56 | 0.54 |