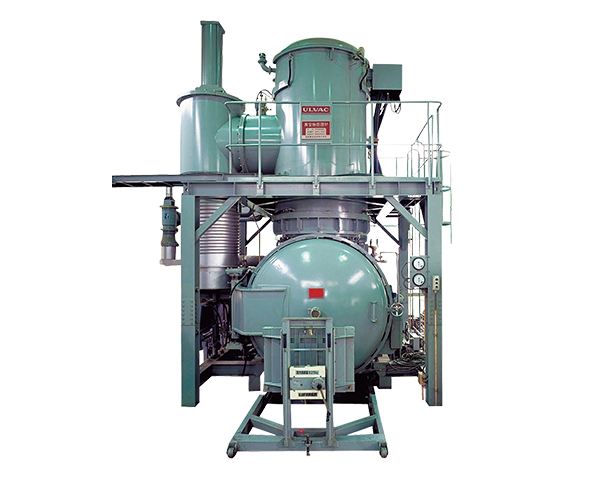

Vacuum Furnace

Model: FHV

FHV series are used for various purposes such as quenching, tempering and brazing of various metals. Vertical two-chamber configuration which consists of heating chamber + preparation/cooling contributes to space saving by adopting elevation mechanism. Temperature data from heating process to cooling process can be seamlessly recorded for quality control of products.

Features

- Maximum temperature 1350ºC, Operation temperature 800 to 1150ºC

- Temperature uniformity is within ±5ºC at 1150ºC

- Keeping the heating chamber in vacuum for high quality and repeatability of products.

- Optional rotating cooling mechanism is suitable to process long products such as cutting tools.

- Thermocouple can be directly set on processing products for historical data of products temperature from heating to cooling as precise quality control.

Applications

- Quenching, Tempering : various machine parts, parts for air plane.

- Brazing : Heat exchanger, machine parts, parts for air plane, vacuum interception.

Specifications

| Model | 45C | 60C | 90C | 120C | |

| Uiform hot zone | Diameter [mm] | 450 | 600 | 900 | 1200 |

| Height [mm] | 450 | 600 | 900 | 1200 | |

| Loading capacity [kg] | 180 | 320 | 900 | 1200 | |

| Temperature | Max. Temp. [℃] | 1350 | |||

| Operation Temp. [℃] | 800 ~ 1150 | ||||

| Temp. uniformity [℃] | 1150 ± 5 | ||||

| Vacuum | Ultimate pressure [Pa] | 3 x 10-3 | |||

| Cooling | Cooling pressure [kPa・abs] | 90 / 190 | |||

* Chamber used:P=Preparation(loading/unloading)Chamber,H=Heating Chamber,G=Gas Cooling Chamber,L=Oil Cooling Chamber