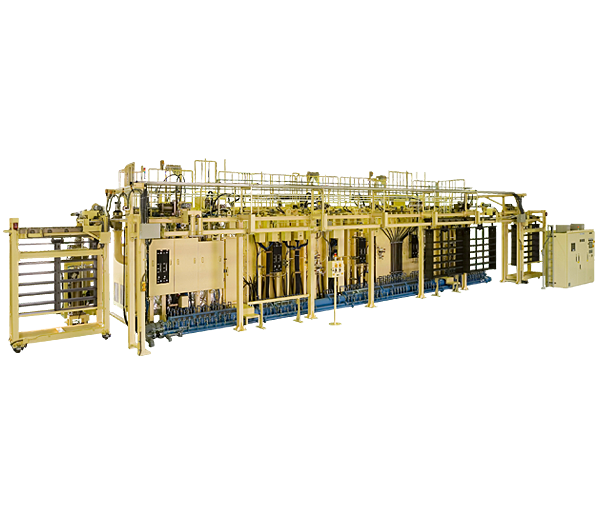

Vacuum Furnace

Model:FBC

This system specializes in the vacuum brazing process to ensure reliable brazing, high productivity and high quality.

Features

- The brazing chamber is kept in a vacuum to achieve superior brazing quality under a stable atmosphere.

- A carrier gas system is implemented to maintain a clean atmosphere under low vacuum, equivalent to high vacuum.

- A pre-heating chamber is implemented at the front side of the brazing chamber to minimize temperature unevenness in the effective heat zone.

- The preparation chamber wall is kept at a stable temperature by residual heat to degas and prevent the absorption of moisture and oil.

- The transfer system is of the rack and pinion type to ensure reliable handling.

- A semi-automatic return line is included as standard for high productivity.

Applications

- Nickel brazing for EGR cooler

- Cupper brazing for oil cooler

- Nickel, cupper, silver brazing for various parts

Specifications

| Model | 317C | 418C | |

| Uniform zone | Width [mm] | 310 | 400 |

| Height [mm] | 1300 | 1300 | |

| Length [mm] | 1700 | 1800 | |

| Loading capacity [kg] | 450 | 450 | |