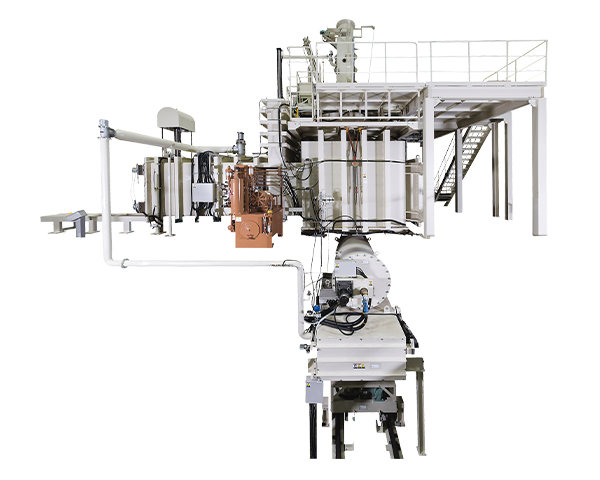

Vacuum Melting Furnace

Model: Magcaster/FMI

Magcaster / FMI is a vacuum melting furnace that uses induction heating to melt functional materials. It employs the strip casting method and is ideal for producing magnetic materials.

Features

- It is possible to melt alloys including active metals such as neodymium, aluminum, titanium, and magnesium, which are rare earth metals essential for functional materials.

- The raw material addition mechanism makes it possible to produce alloys of metals with different melting points and vapor pressures.

It has a fixed amount pouring program as standard, allowing for highly reproducible tilting and pouring. - By combining a water-cooled roll cooling mechanism, a water-cooled drum cooling mechanism, and a collection container mechanism, it is possible to produce thin flakes of uniform size.

- The collection container mechanism allows the active metals to be collected in a container after melting without coming into contact with oxygen.

Applications

- Rare-earth metals : Magnets (Nd-Fe-B, Sm-Co)

- Magnetic materials

- Hydrogen-absorbing alloys

Specifications

| Model | Magcaster-600C | Magcaster-800C | FMI-600C |

| Melting type | Induction melting | ||

| Melting voluum [kg] | 600 | 800 | 600 |

| Cooling type | Cooling roller + Rotary spiral drum + Collection container | Cooling roller + Cooling disc | |