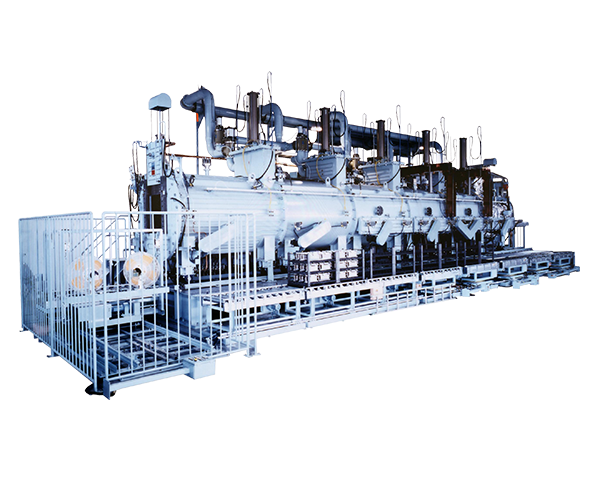

Vacuum Furnace

Hot Roller Type

Hot Roller Type

Vacuum Heat Treatment FurnaceFHHn series

FHH series are used for various purposes, such as tempering, sintering, brazing of various types of metal.

Features

- Adopting hot roller carry system, chamber configuration can be multiplied by combining each unitized chambers.

- System configuration is selectable depending on process and throughput, such as preparation chamber(vacuum/atmosphere),preheating chamber(operation 500ºC),heating chamber(operation 1150ºC), cooling chamber.

- Adopting double gate valve, each chamber is completely isolated. A vacuum/atmosphere is completely isolated.

- Units can be added depending on process and throughput.

- Inline process is possible, as below.“Loading→Heating 1→Cooling 1→Heating 2→Cooling 2→Unloading”.

- Adopting six sectional temperature control system heater(option), temperature uniformity can be 1150ºC±3ºC.

Applications

- Vacuum heat treatment : Heat treatment of various metals, brazing.

- Sintering : Magnet.

Specifications

| System / Type | 3060 | 6090 | 6150 | Remarks | ||

| Performance | ||||||

| Size | Uniform hot zone (㎜) | Width | 300 | 600 | 600 | |

| Length | 600 | 900 | 1500 | |||

| Height | 500 | 600 | 600 | |||

| Loading capacity (㎏) | 230 | 500 | 800 | including tray's weight | ||

| Temperature | Max. temperature | Preheating | 600ºC | |||

| Heating | 1200ºC | |||||

| Operation temperature | Preheating | 500ºC | ||||

| Heating | 1100ºC | |||||

| Temperature uniformity | Preheating | 500±5ºC | Five points measurement at no load | |||

| Heating | 1100±5ºC | |||||

| Heating (special) | 1100±3ºC | High temperature type is optional |

||||

| Cooling | Gas cooling | Standard | 80kPaG | selectable Ar.N2 | ||

| Pressurized type | 190kPaG | |||||

| Vacuum | Ultimate vacuum | Standard | 10-1Pa order | At degassed and empty conditions | ||

| High vacuum type | 10-3Paorder | |||||

| Operation pressure | Standard(1) | 1Pa〜10Pa | (1) At low vacuum mode | |||

| Standard(2) | 10Pa to 100Pa | (2)At carrier gas mode | ||||

| High vacuum type | 10-2Pa to10-1Pa | |||||

| Pump-down time (min) |

Loading | 10min or less | from atmosphere to 10Pa or less at no load | |||

| Cooling | 10min or less | |||||

| Cooling | 10min or less | |||||

| Leak rate (Pa・m3/s) |

Loading | 4×10-4or less | by pressure rise method | |||

| Preheating | 4×10-4or less | |||||

| Heating | 2×10-4or less | |||||

| Cooling | 4×10-4or less | |||||

| Utility | ||||||

| 3chambers type (Preheating×1 Heating×1 Cooling×1) |

Power requirement (kVA) | 210 | 300 | 480 | Primary power requirement | |

| Cooling water requirement (m3/hr) | 12 | 15 | 18 | Temperature:20 to 30ºC | ||

| Compressed air requirement (Nm3/min) | 1000 | 1100 | 1100 | |||

| Carrier gas requirement (L/min) | 80 | 80 | 200 | Limit of flowmeter | ||

| Coling gas requirement (m3/times) | 4 | 9 | 12 | At the condition of pressurized cooling (190kPa) | ||

| Floor space requirement (m2) | Width | 8.5 | 10 | 12 | ||

| Length | 8.5 | 10 | 13 | |||

| Height | 4.5 | 5.8 | 5.8 | |||

| 5chambers type (Preheating×2 Heating×2 Cooling×1) |

Power requirement (kVA) | 390 | 425 | 750 | Primary power requirement | |

| Cooling waterrequirement (m3/hr) | 20 | 25 | 30 | Temperature:20 to 30ºC | ||

| Compressed air requirement(Nm3/min) | 1000 | 1100 | 1100 | |||

| Carrier gas requirement (L/min) | 120 | 160 | 300 | Limit of flowmeter | ||

| Coling gas requirement (m3/times) | 4 | 9 | 11.7 | At the condition of pressurized cooling (190kPa) | ||

| Floor space requirement (m2) | Width | 8.5 | 10 | 12 | ||

| Length | 11.5 | 12.5 | 17.5 | |||

| Height | 4.5 | 5.8 | 5.8 | |||