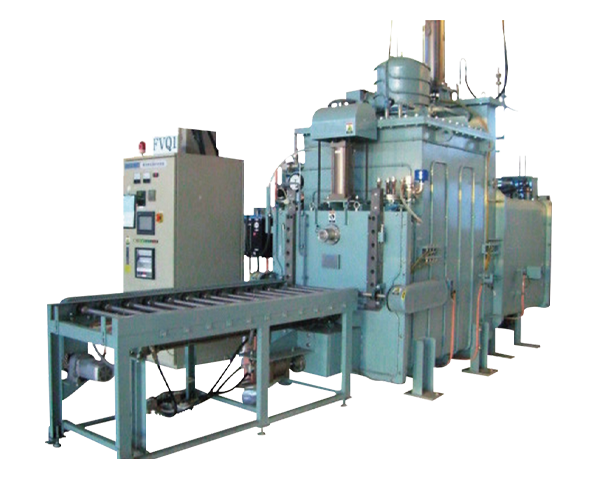

Vacuum Furnace

Horizontal Type

Horizontal Type

Vacuum Heat Treatment FurnaceFHH series

FHH series are used for various purposes such as quenching, tempering, sintering and brazing of various metals. Chamber configuration can be multiplied up to 3 chambers by adopting fork carry system.

Features

- Maximum temperature1350ºC,Operation temperature800 to 1150ºC

- Temperature uniformity is within ± 5ºC at 1150ºC

- Keeping the heating chamber in vacuum for high quality and repeatability of products.

- Carrier gas system is implemented to minimize metal evaporation.

- At cooling process, heating chamber is not cooled so that power consumption can be saved.

- The heating chamber is kept in vacuum to prevent from oxidizing so that lifetime for internal parts of the heating chamber can be longer.

- Water-cooling jacket construction contributes clean work environment.

Applications

- Quenching, Tempering : Various machine parts, Dies.

- Sintering : Superhard tools, Magnet.

- Brazing : Heat exchanger, machine parts.

Specifications

| System / Type | 45 | 60 | 75 | 90 | 120 | Remarks | |||

| Performance | Size | Uniform hot zone 〔㎜〕 | Width | 450 | 600 | 750 | 900 | 1200 | |

| Length | 675 | 900 | 1125 | 1350 | 1800 | ||||

| Height | 300 | 400 | 500 | 600 | 800 | ||||

| Loading capacity 〔㎏〕 | 200 | 400 | 650 | 1000 | 2000 | including tray's weight | |||

| Temperature | Max. temperature | 1350ºC | |||||||

| Operation temperature | 800 to 1150ºC | ||||||||

| Temperature uniformity | 1150ºC ± 5ºC | Five points measure ment at no load | |||||||

| Cooling | Gas cooling | 93 kPa (700 Torr) | 30minutes or less | from 1150ºC to 150ºC when standard specimen is charged. | |||||

| 190 kPa (1.9㎏/ cm2 G) | 20 minutes or less | ||||||||

| Handling time to oil quenching pit | 12sec | 15sec | 20sec | ||||||

| Vacuum | Ultimate vacuum | 10-1Pa(10-3Torr) order. *High vacuum 10-3Pa (10-5 Torr) order is option. | At degassed and empty conditions | ||||||

| Operating pressure | 133 to13Pa (1〜10-1Torr) | ||||||||

| Pump-down time | 10minutes or less | 15minutes or less | from the atmosphere to 6.5Pa (5×10-2 Torr) at no load | ||||||

| Leak rate 〔Pa・m3 /S〕 | 3 × 10-4 | 4 × 10-4 | 4 × 10 -4 | 5 × 10 -4 | by pressure rise method | ||||

| Utility | Power require -ment 〔kVA〕 | GH* | 65 | 101 | 161 | 209 | 303 | AC 200/220V (90& 120 type, 400/440V) 50/60Hz 3φ | |

| G/L.H* | 73 | 110 | 187 | 244 | 354 | ||||

| PHG* | 70 | 109 | 175 | 228 | 333 | ||||

| GHL* | 85 | 130 | 223 | 300 | 429 | (Primary power requirement) | |||

| Cooling water require ment 〔kVA〕 | GH* | 3 | 5 | 7 | 9 | 16 | Pressure 2.5/cm2G (250KPa) Temper ature 30ºC or less ※25ºC or less : Oil diffusion pump type | ||

| G/L.H* | 3 | 4 | 5 | 7 | 11 | ||||

| PHG* | 4 | 5 | 8 | 11 | 18 | ||||

| GHL* | 4 | 6 | 9 | 11 | 18 | ||||

| Compressed air require ment 〔Nm3 /min〕 | Some | 7㎏/ cm2G (700 KPa) | |||||||

| Carrier gas require ment 〔L/min〕 | 1.5 | 2 | 3 | 4.5 | 6 | N2 gas (N.T.P) | |||

| Cooling gas require ment 〔m3/times〕 | 2.7 | 4.5 | 6 | 10 | 18 | N2 gas (N.T.P) | |||

| Quenching oil require ment 〔m3〕 | 1.8 | 3.6 | 6 | 9 | ─ | ||||

| Quenching oil heater 〔kW〕 | 15 | 24 | 48 | 72 | ─ | ||||

| Floor space require ment 〔m2〕 | 2chamber type | 3.4× 5.7 | 3.9× 7.4 | 4.6× 8.7 | 5.5× 9 | 7× 12.5 | W×L | ||

| 3chamber type | 3.4× 8.1 | 3.7× 9.4 | 4.6× 10.6 | 5.5× 12 | 7× 17 | ||||

| Gtype PHG | 3.5× 0.5 | 3.9× 0.5 | 5× 0.5 | 5.5× 0.5 | 6.5× 0.5 | H×D | |||

| Ltype GHL | 3.5× 1.0 | 4× 1.4 | 5× 1.5 | 5.5× 1.8 | 6.5× 2.4 | ||||

* Chamber used:P=Preparation(loading/unloading)Chamber,H=Heating Chamber, G=Gas Cooling Chamber,L=Oil Cooling Chamber