News Category

ULVAC-RIKO announces Resonance Shear Measurement System (RSM-1), the world's first ever commercially available solution for the evaluation of viscosity, friction, and lubrication properties for confined liquids at nano-scale thickness.

ULVAC-RIKO, Inc. (Pres. Dr. Yoshikazu Ishii) announces today the release of the world's very first Resonance Shear Measurement System (RSM-1), developed with the assistance of the Japan Science and Technology Agency (JST); and made possible by the research breakthroughs of Prof. Dr. Kazue Kurihara of Tohoku University, specifically the studies of the resonance shear method for evaluating liquid properties in nanospace, and the twin-path method for measuring the surface force between opaque substrates.ULVAC-RIKO, Inc. (Pres. Dr. Yoshikazu Ishii) announces today the release of the world's very first Resonance Shear Measurement System (RSM-1), developed with the assistance of the Japan Science and Technology Agency (JST); and made possible by the research breakthroughs of Prof. Dr. Kazue Kurihara of Tohoku University, specifically the studies of the resonance shear method for evaluating liquid properties in nanospace, and the twin-path method for measuring the surface force between opaque substrates.

[Background]

It is known that decreasing the liquid film thickness confined between two solid surfaces below the nanometer range, the film can achieve unique properties such as ordered structure formation and drastic increase in viscosity, due to confinement and interface effects, of which are completely different from those of bulk liquid. Liquid film thickness, of which determines the property of bulk liquid, is strongly dependent upon liquid-liquid and liquid-solid surface interaction. Various shear measurement techniques employing the surface forces apparatus (SFA) have been developed and used for measuring various properties of confined liquids such as viscosity, friction, and lubrication. It is not possible, however, to evaluate all of these properties without using different sets of techniques (Table. 1).The Resonance Shear Measurement System (RSM-1) enables the measurement of resonance shear response and is able to evaluate all of their properties by continuously changing the thickness of liquid film confined between two solid surfaces at nanometer resolution. In addition, the surface potential, adhesive force, and steric structures of adsorbed molecules can be evaluated using surface forces measurement.

[Principle]

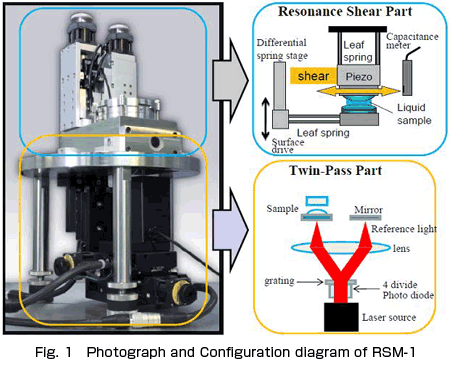

As shown in Fig.1, liquid film thickness between two solid surfaces is controlled at nanometer resolution, resonance shear response is observed during horizontal oscillation of the upper surface using the resonance method. Utilizing the mechanical resonance response of the shear unit with the upper surface, we measure the values of the frequency and amplitude of the resonance peak. From these values, we can evaluate the liquid property change. Using the large response at the resonance frequency, high sensitivity measurement is made possible.This apparatus has utilizes a two-beam (twin path) interferometry technique, which is the method to determine the thickness of the confined liquid in the surface force apparatus via reflection interferometry. Using this method, it is possible to measure even opaque samples, which is not measurable using conventional surface forces apparatus.

[Main Feature]

1. Shear response sensitivity --- Highly sensitive due to the resonance method

2. Fast measurement time --- Quick measurements via Fast Fourier transform method (2 to 10 seconds)

3. Determination of the thickness of the liquid confined between surfaces --- Resolution of the twin-path method (1nm), resolution of FECO method (0.1nm).

4. Opaque samples --- Usable samples include metal, ceramic, polymer, etc.Liquid samples --- Including lubricant oil, electrolyte, polymer solution, surfactant solution, etc.

5. Measurable properties --- Surface properties (Surface potential and charges, adsorption properties such as steric structure and viscoelastic properties of adsorbed molecules), rheology (viscosity of liquid) and tribology (friction and lubrication) in confined liquid, Elucidation of origin of interaction.

[Example]

•Water confined between mica surfaces

→ Observation of gradual structuring and increase in the viscosity for water below 1 nm of the liquid thickness.

•Lubricant oil and its model system

→ Observation of frictional and lubrication properties, effects of additives, and stick-slip phenomena.

•Effects of surface modification for calcium carbonate nanoparticles, which is applied for increasing viscosity

→ Elucidation of the mechanism for viscosity increase due to dispersion medium, dioctyl phthalate (DOP).

[Application]

•The mechanism involved in friction has traditionally only been understood in a phenomenological manner; however, this system allows concrete evaluations of the friction system at the molecular level. This opens up the possibility for more efficient system design, reducing friction and energy loss due to friction, and opens the door to future innovations in technologies such as superlubricity.

•Provides designing principles at the nanometer level for many advanced materials, invigorating industries manufacturing innovative, high-valued materials.

[Specification and Utility]

1. Specification

Measurement temperature: Room temperature

Sample Volume: nonvolatile liquid 20〜30 μl

Measurement Mode:

Shear resonance measurement: Frequency scanning method

Fast Fourier Transform method

Surface forces measurement:

Maximum resolution for distance between solid surfaces: 1 nm (0.1 nm via FECO option)*1

*1Note: Dependence on the measurement environmentEffective distance between solid surfaces: from 5 μm to contact point.

2. Utility

Power Source: AC 100 V 20 AInstallation Area: Ca.900mm (W)×Ca.700mm (D)

[Sales Information]

The RSM-1 is intended for manufacturers in fields such as cosmetics, lubricants, automobiles, paint and sealants. The RSM-1 is priced at 32 million yen.The Resonance Shear Measurement System will be exhibited at JST's booth (B-15) at nano tech 2010: International Nanotechnology Exhibition & Conference, which will be held at the Tokyo Big Sight from Feb. 17th to 19th

For further information

ULVAC-RIKO, Inc. Sales.

http://www.ulvac-riko.co.jp/English/index_eng.htm

Table 1 Comparison between conventional technology and technology used in Resonance Shear Measurement system (RSM-1).

Conventional technology(Shear measurement via Surface Force Apparatus (SFA) (Israelachivili and Kline at al.)) Resonance Shear Measurement System (RSM-1)Sensitivity of shear response ○○Surface force only. Resonance method is not possible. ◎Highly sensitive via resonance method.◎Quick measurements to be made via the Fast Fourier transform method (2 to 10 seconds)Control and measurement of surface distance ◎Resolution 0.1 nm(fringes of equal chromatic order, FECO) ◎Resolution 0.1 nm (FECO) 1.0 nm (twin-path)Usable sample △Transparent samples only ◎Transparent and Opaque samplesMeasurement Property △Rheology and tribology requires separate devices ◎Integrated system for both rheology and tribology

[Explanation of technical terms]

1. Surface forces apparatus

Using surface forces apparatus, we directly measure the interaction force between two solid surfaces changing surface separation at nanometer resolution. This is useful for elucidating the origin of force and evaluating the properties of solid-liquid interface (surface charge, salvation force, adhesive force: for example, structure and rigidity of adhesive polymer). One surface is held by a cantilevered spring, and the deflection of the spring is used to calculate the surface force.

2. Confined liquid

When the thickness of the liquid between the two solid surfaces become about the nanometer range, which is as same thickness as several times in a molecule, the liquid has unique and different properties from bulk liquid such as the ordered structure formation and the drastic increase of the viscosity etc due to confinement and interface effects. This is so called "confined liquid". For the chemical reaction in the porous catalyst and the flow of liquid in the micro or nano-sensor, it is important to evaluate such confined liquid properties.

3. Shear resonance measurement

The resonance shear measurement system (RSM-1) measures the surface force and resonance shear response by continuously changing the thickness of liquid film confined between two solid surfaces at nanometer resolution. The liquid thickness is controlled and determined using interferometric methods in surface forces apparatus. The shear response via resonance method provides sensitive detection for the tiny change of the liquid properties between substrates. We can evaluate the viscosity change associated with the liquid structuring, frictional/lubricational property, and so on, with changing the liquid film thickness.

4. Twin-path interferometric method

Twin-path interferometric method is the method to determine the thickness of the confined liquid in the surface forces apparatus via reflection interferometry. The thickness of the liquid is determined in conventional surface forces apparatus using the fringes of equal chromatic order (FECO) method which requires the transparent samples. We can't measure any opaque samples using the conventional surface forces apparatus, but using reflection interferometry by twin-path method.

5. Nano-rheology

Rheology is the research field for viscoelasticity. It is important for mainly polymer molding, paint, food and so on. Evaluation of rheological properties at nanometer order gives the system design guide at the molecular level for the fluid process of the liquid in the microsensor, particle dispersion, and the lubricant, etc.

6. Nano- tribology

Tribology is the research field for friction/lubrication/wear. It is important to elucidate the tribological properties in the cases of the movement with object contact such as a piston and cylinder in the engine, machine parts like bearing and tire etc. Tribology at nanometer scale is important to elucidate phenomena at the molecule level in macroscopic tribology and to understand friction/lubrication for hard disk, nano-micro machine and so on.

<Reference>

1) J. N. Israelachivili, Intermolecular and Surface Forces, Third Edition, edited by Academic Press.

2) H. Kawai, H. Sakuma, M. Mizukami, T. Abe, Y. Fukao, H. Tajima, and K. Kurihara, Rev. Sci. Instrum. 80 (2008) 043701.

3) K. Kurihara, EKISHO, 6, 34 (2002).

4) M. Mizukami, K. Kusakabe, and K. Kurihara, Prog. Colloid Polym. Sci., 128, 105 (2004).

5)H. Sakuma, K. Otsuki, K. Kurihara, Phys. Rev. Lett., 96, 046104 (2006).

6) H. Mizuno, T. Haraszti, M. Mizukami, K. Kurihara, SAE Int. J. Fuels Lubr. 1, 1517 (2009).