News Category

Exatec*, ULVAC Announce Technology Collaboration for Mass Production of Coating Solutions to Drive Use of Polycarbonate for Car Windows

Exatec*, a wholly owned subsidiary of SABIC Innovative Plastics, and ULVAC, a leader in mass-production vacuum technologies, today announced their collaboration to accelerate cost-effective, high-volume production of weatherable, scratch-resistant, plasma-coated Lexan* polycarbonate (PC) resin for vehicle windows. Under the agreement, ULVAC will manufacture turnkey mass production systems that leverage its' expertise in high-volume vacuum equipment and Exatec's proprietary plasma coating technology.

The combined ULVAC and Exatec technologies will help automakers and tiers replace heavier glass windows with Lexan resin glazing to meet upcoming regulations for lower CO2 emissions and also provides greater design freedom and cost reduction through parts consolidation. It also offers other industries - particularly consumer electronics - durable and abrasion-resistant coating solutions for a broad range of products. Automakers interested in expanding production of PC windows using Exatec technology will soon be able to order machinery from ULVAC.

"Pressure to reduce vehicle emissions is increasing worldwide, requiring automakers to implement weight-out solutions that can also meet rising demand for superior quality and durability," said Dominic McMahon, chief executive officer, Exatec. " Plasma-coated Lexan PC glazing has exceptionally high potential for weight-out. This technology is already validated, and now our relationship with ULVAC builds the path to large-scale production. We are confident that ULVAC's turnkey solutions combined with Exatec's coating technology will change the future of automotive glazing and make a significant contribution to improved fuel economy, reduced emissions and increased vehicle range."

"The technical cooperation between Exatec and ULVAC will no doubt accelerate the full scale production of plasma-coated polycarbonate automotive glazing," said Kyuzo Nakamura, chairman of ULVAC, Inc. "Exatec's superior technology for hard coating polycarbonate is already in production and ULVAC has been engaged in production and distribution of various types of vacuum coating equipment. We believe that this technical cooperation will bring a total solutions package to our customers in automotive and also in consumer electronics."

"SABIC Innovative Plastics recognized the need for new materials that offer automotive designers greater freedom in styling while reducing the weight of glazing components," said Greg Adams, vice president, Automotive, SABIC Innovative Plastics. "Over the past few years Exatec coatings and Lexan have been used for the glazing on many technology demonstration vehicles from innovative OEMs. This technology collaboration with ULVAC is a milestone in the broader adoption of PC glazing in the automotive industry."

More stringent vehicle emission restrictions are planned in major automotive markets. In the United States, new rules mandate that by 2016, vehicles must get an average of 35.5 miles per gallon. In Europe, mandatory reductions of CO2 emissions aim to reach 130gCO2/km (.46lbs/mile) in 2015 for the average new car fleet, and 95g/km (.35lbs/mile) by 2020.

Plasma-Coated PC Glazing Industrialization

The joint solution created by Exatec and ULVAC combines two highly advanced technologies and optimizes them for large-scale production. Exatec's plasma coatings for Lexan PC provide unmatched weatherability and abrasion resistance to ensure crystal-clear, attractive and durable glazing over the life of the vehicle. ULVAC's advanced vacuum equipment technologies enable this coating system to be scaled up for production; they feature a high deposition rate, a continuous process and the ability to coat parts with complex shapes and a wide range of sizes. Together, the companies have optimized this system for exceptional quality, consistency and throughput.

About ULVAC, Inc.

ULVAC (President: Hidenori Suwa) was established as a pioneer of vacuum technology in Japan in 1952. ULVAC has grown with progress of vacuum technology. Now ULVAC is only one company that supplies to customers products and service based on vacuum technology for application of display device such as LCD, PDP, OLED, various types of electric components and semiconductors, automobile parts, pharmaceuticals and so on. ULVAC Group has net sales of 224 billion Yen and 6900 employees as of June in 2009. ULVAC enhances customer satisfaction by offering total solution package not only with supply of equipments and parts but also with supply of integrated production line, material, foundry service, maintenance, improvement plan, etc. ULVAC is going ahead with product development in the new fields other than vacuum technology and will contribute to progress of industry.

About SABIC Innovative Plastics

SABIC Innovative Plastics is a leading, global supplier of engineering thermoplastics with a 75-year history of breakthrough solutions that solve its customers' most pressing challenges. Today, SABIC Innovative Plastics is a multi-billion-dollar company with operations in more than 35 countries and approximately 9,000 employees worldwide. The company continues to lead the plastics industry with customer collaboration and continued investments in new polymer technologies, global application development, process technologies, and environmentally responsible solutions that serve diverse markets such as automotive, electronics, building & construction, transportation, and healthcare. The company's extensive product portfolio includes thermoplastic resins, coatings, specialty compounds, film, and sheet. SABIC Innovative Plastics (www.sabic-ip.com) is a wholly owned subsidiary of Saudi Basic Industries Corporation (SABIC), one of the world's top six petrochemicals manufacturers.

About EXATEC

Exatec, LLC (www.exatec.biz) is a wholly owned subsidiary of SABIC Innovative Plastics. Founded in 1998, Exatec offers the industry's widest range of enabling technologies for advanced polycarbonate glazing systems, including an exclusive offering of the Exatec glass-like plasma coating technology.

Building on SABIC Innovative Plastics' extensive materials and molding competence, Exatec's technology solutions encompass all processes and manufacturing steps, including next-generation polycarbonate materials, molding with added functionality, wet-coat and plasma enhanced chemical vapor coatings, part marking and heated window defrosting.

Exatec's advanced plasma coating systems ensure market-leading weathering, durability and glass-like abrasion performance. These plasma-coating technologies are capable of delivering cost effective, complex shaped parts with high yield and fast production rates.

Exatec is headquartered at its 100,000 sq. ft. state-of-the-art Glazing Technology Development Center in Wixom, Michigan (USA).

* Trademarks of SABIC Innovative Plastics IP BV.

Photos:

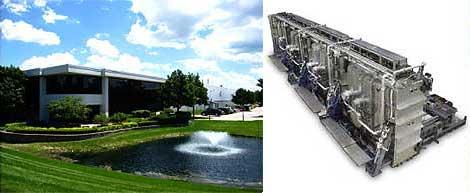

The Exatec Glazing Technology Development Center, Wixom, MI, USA

ULVAC Multi Chamber and Vertical Sputtering System for TFT LCD

For further information

ULVAC, Inc. web_info

< SABIC Innovative Plastics Media Contact >

Global

SABIC Innovative Plastics, Jodi Kennedy

TEL:+1-413-448-7383

E-MAIL: jodi.kennedy@sabic-ip.com

< SABIC Innovative Plastics Agency Media Contacts >

The Americas

AH&M Marketing Communications, Jim Allison

TEL:+1-413-448-2260, x250

E-MAIL: jallison@ahminc.com

Brazil

Edelman Brazil, Gabriela Bruschi

TEL:+55-11-3017-5300, x221

E-MAIL: gabriela.bruschi@edelman.com

Europe

Marketing Solutions, Kevin Noels

TEL:+31-164-317-011

E-MAIL: knoels@marketingsolutions.be

China

Edelman, Shona Liu

TEL:+86-21-6193-7526

E-MAIL: shona.liu@edelman.com

Japan

Tokyo PR Inc., Mitsu Sugino

TEL:+81-3-3273-2731

E-MAIL: sugino@tokyopr.co.jp

< Websites >

ULVAC, Inc. www.ulvac.co.jp/eng/

SABIC Innovative Plastics www.sabic-ip.com