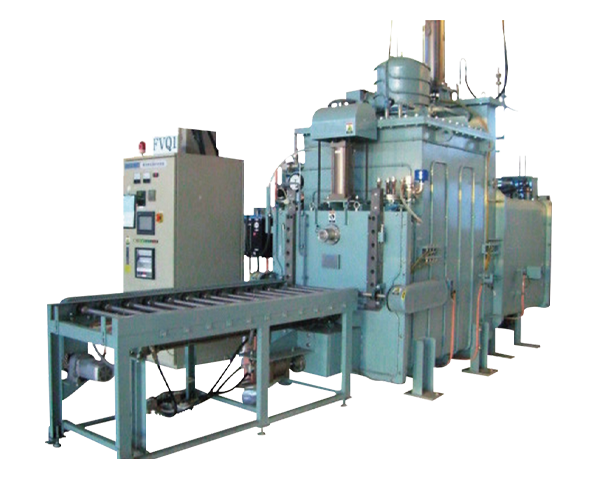

Vacuum Furnace

Model: FHH

FHH series are used for various purposes such as quenching, tempering, sintering and brazing of various metals. Chamber configuration can be multiplied up to 3 chambers by adopting fork carry system.

Features

- Maximum temperature1350ºC,Operation temperature800 to 1150ºC

- Temperature uniformity is within ± 5ºC at 1150ºC

- Keeping the heating chamber in vacuum for high quality and repeatability of products.

- Carrier gas system is implemented to minimize metal evaporation.

- At cooling process, heating chamber is not cooled so that power consumption can be saved.

- The heating chamber is kept in vacuum to prevent from oxidizing so that lifetime for internal parts of the heating chamber can be longer.

- Water-cooling jacket construction contributes clean work environment.

Applications

- Quenching, Tempering : Various machine parts, Dies.

- Sintering : Superhard tools, Magnet.

- Brazing : Heat exchanger, machine parts.

Specifications

| Model | 45C | 60C | 75C | 90C | 120C | |

| Uniform zone | Width [mm] | 450 | 600 | 750 | 900 | 1200 |

| Height [mm] | 300 | 600 | 650 | 600 / 1000 | 800 | |

| Length [mm] | 675 | 900 | 1125 | 1350 | 1800 | |

| Loading capacity [kg] | 200 | 400 | 800 | 1000 | 2000 | |

| Temperature | Max. Temp. [℃] | 1350 | ||||

| Operation Temp. [℃] | 800 ~ 1150 | |||||

| Temp. uniformity [℃] | 1150 ± 5 | |||||

| Vacuum | Ultimate pressure [Pa] | 3 x 10-3 | ||||

| Cooling | Cooling pressure [kPa・abs] | 90 / 290 | ||||

* Chamber used:P=Preparation(loading/unloading)Chamber,H=Heating Chamber, G=Gas Cooling Chamber,L=Oil Cooling Chamber