This post is also available in: Japanese

Sputtering is a method of thin film deposition, which is a type of PVD (physical vapor deposition).

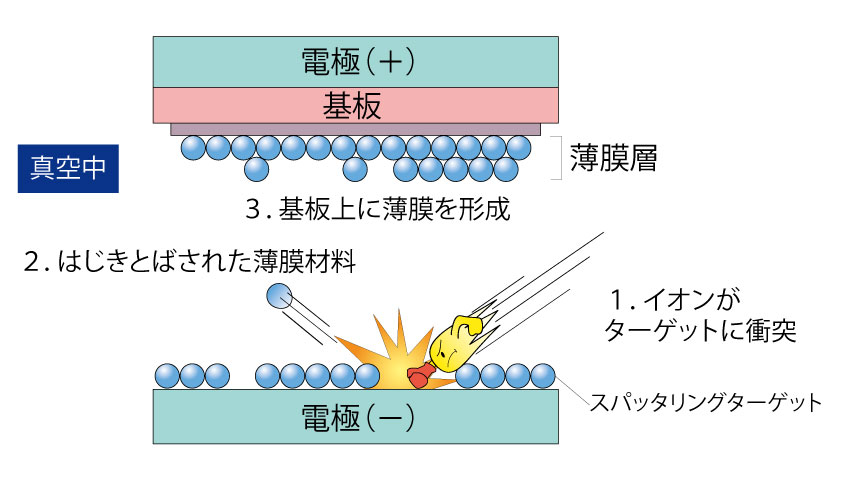

In this process, a substrate to be coated with thin film (glass substrate, Si-wafer, etc.) and target (material for the thin film) are placed into a vacuum chamber, that becomes filled with an inert gas (generally, Argon). When high voltage of electricity is applied, positively charged Argon (Ar+) becomes attracted to a negatively charged target material as cathode, and collides into it. Upon the collision, target atoms/molecules are “sputtered off” and deposits on the substrate, coating it in a thin film.

Sputtering is conducted in a vacuum to keep the process sterile and free of contamination or impurities.

Sputtering process can be illustrated as below:

Sputtering traits:

- Strong adhesion

Positively charged ions acceletate into the target material at the velocity of approximately ~50 eV. This makes it possible to work with targets with relatively high melting point. - Excellent step coverage

Due to high process pressure, the average free process of the molecule is short. Sputtered molecules experience mid-air scattering, increasing the anisotropy of the process. - Excellent film thickness uniformity

Due to sputtering target’s large surface area, high film thickness uniformity is relatively easy to achieve. - Alloy film deposition

Possibly by simply using alloy as target. - Unrestricted installment direction of cathodes/anodes, etc.

- Easy transition to single-wafer processing

High reproducibility, time power controllableness and low target replacement frequency makes the process compatible with mass-production.

What is magnetron sputtering?

Magnetron sputtering deposition is a method in which magnets/electromagnets are used to generate a magnetic field perpendicular to the electric field near the electrode.

The presence of a magnetic field allows electrons to gather in the field, generating high electron density. This increases the chance of electrons colliding with Ar, accelerating the formation of Ar+. The increased Ar+ is attracted to the negatively charged target and sputters at a higher rate, resulting in increased deposition rate.

This method also can be used with DC (direct current), RF (radio frequency), AC (alternating current) discharges. Learn more below:

Why use Argon?

In sputteirng, Argon, a rare gas element, is used for the incident charged particles, due to its:

- high sputtering rate

- inert nature – unlikely to react with other elements

- low price

- availability of pure gas

Other rare gas elements, Krypton (Kr) and Xenon (Xe), are also used occasionally.