This post is also available in: Japanese Chinese (Simplified)

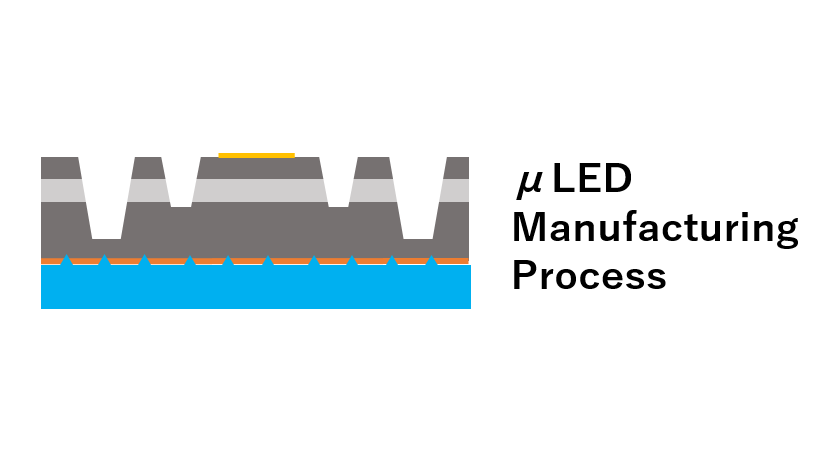

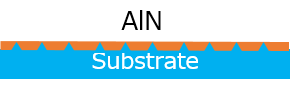

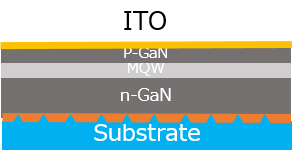

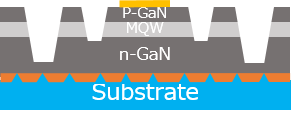

MicroLED is a technology for refining LEDs used as light sources such as lighting and applying them to displays, and is expected as a technology to realize the next generation of displays of liquid crystal and organic EL. ULVAC provides technologies such as ITO sputtering and etching for the MicroLED manufacturing process.