This post is also available in: Japanese

Dry etching plays an indispensable role in the manufacturing of semiconductors and electronic components.

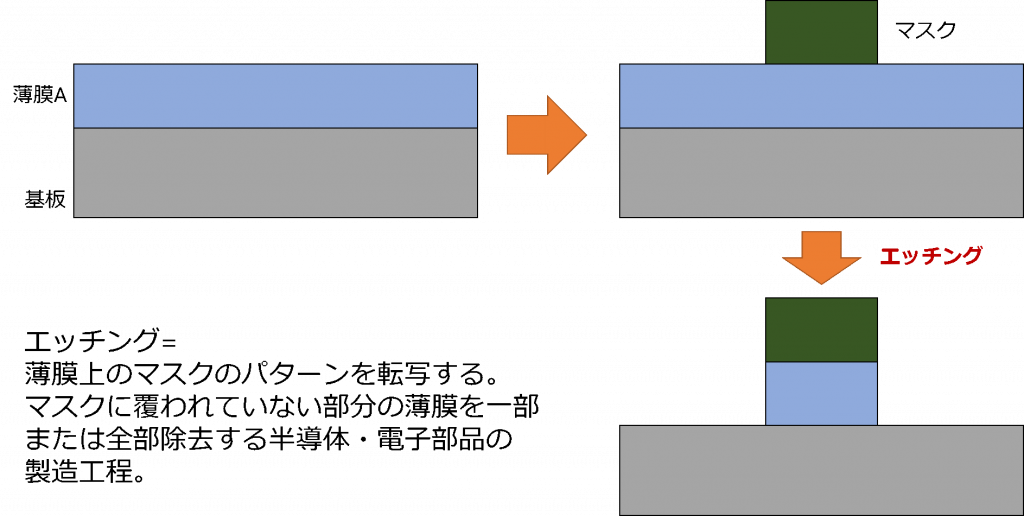

First, etching is a process of removing unwanted portions of depositions on semiconductors. This is done by transferring a mask pattern onto thin film, and removing the leftover part not covered by the mask, leaving the film in a desired shape.

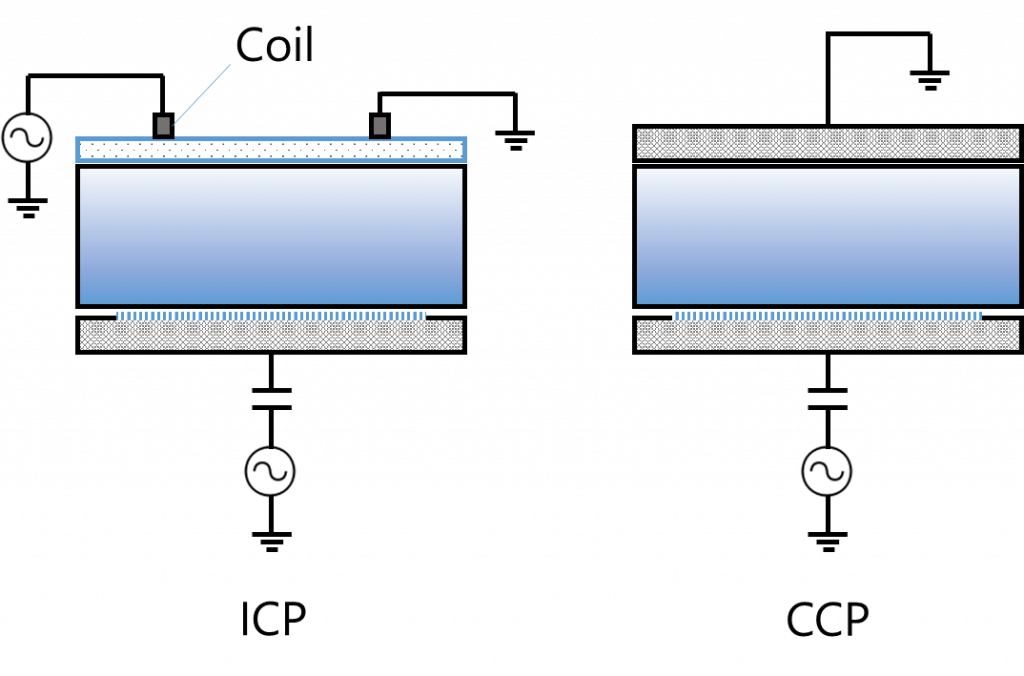

Dry etching generally uses vacuum discharge plasma, such as Inductively Coupled Plasma (ICP) or Capacitive Coupled Plasma (CCP).

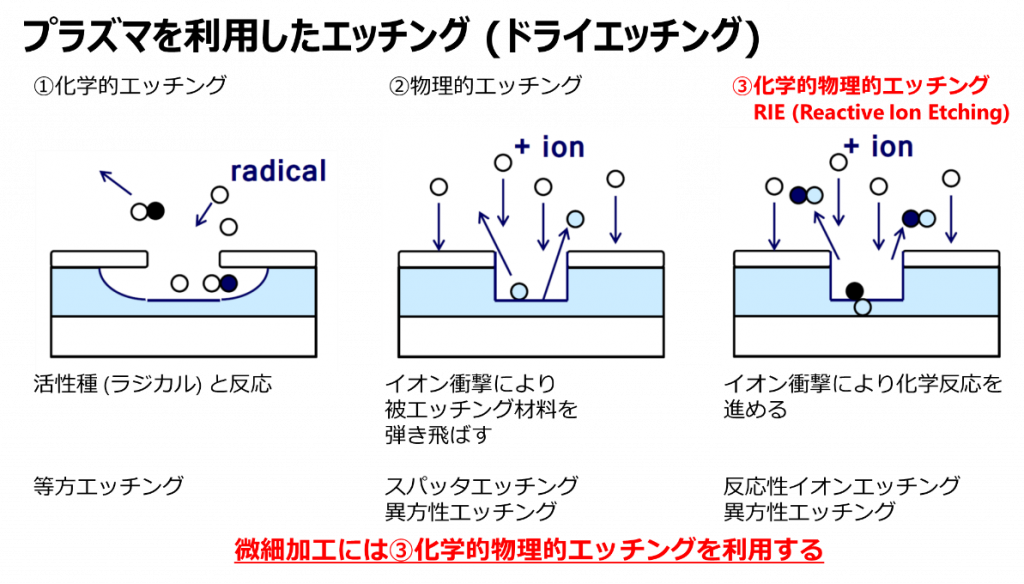

In dry etching, the plasma of a gas that is reactive to the etching target is generated, then a bias is applied to the substrate to attract reactive ions in the plasma to the substrate surface.

Also called Reactive Ion Etching (RIE), this process allows for the pattern transfer to occur more quickly and un-isotopically than non-dry processes. As it uses chemical reaction to convert solid thin film material into gas, accumulation of thin film material elements in the vacuum vessel is prevented, making this process highly fit for stable long-term operation.