This post is also available in: Japanese

1.Introduction

ULVAC CRYOGENICS INC. obtained Cryogenic Equipment Division of Iwatani Industrial Gases Corporation, which produces and sells cryogenic refrigerators and their application products, on May 1, 2014. Cryogenic Equipment Division of Iwatani jointly developed cryogenfree dilution refrigerators with Osaka City University from 2006 to 20131), 5). From 2014, ULVAC CRYOGENICS INC.

has started developing new dilution refrigerators with Osaka City University. This paper reports on the history and progress of these development efforts.

“Low temperatures” are necessary in various fields such as astronomy (cosmic structure), elemental microanalysis, next-generation computers (quantum computers), and new material research (advanced superconductors).

Dilution refrigerators are the solution to generate extremely low temperatures of 1 K to several ten mK for developing next-generation technologies.

Helium atoms have two types of isotopes: one is common 4He with atomic weight of four and another is the lighter 3He with atomic weight of three. Both helium elements are stable and non radioactive, but their physical properties at cryogenic temperatures are completely different.

The dilution refrigerators rely heavily on the differences in physical properties of 3He and 4He.

Until now, wet dilution refrigerators (the conventional type), in which cryogens (liquid nitrogen and liquid helium) are used to precool circulating 3He gas, can achieve a minimum temperature of 2 mK. And cryogen-free dilution refrigerators, in which mechanical refrigerators (4 K pulse tube refrigerators or 4K-GM refrigerators) are used to precool circulating 3He gas, can achieve a minimum temperature of 10 mK.

The advantages of dilution refrigerators are;

(1) The principle of dilution process is simple, so the structure of dilution refrigerator is rather simple too.

(2) High cooling power can be obtained even in low temperature region.

(3) Continuous operation can carry for long term (a few months).

(4) Operation of dilution refrigerators are almost completely unaffected by magnetic fields.

Despite those advantages, dilution refrigerators are not in common use by occasion of below.

(1) The processes required to reach final steady operation are rather complicated and difficult to understand.

(2) There are many valves need to operate and their operation procedures are complicated, so it is not easy for inexperienced operators to use.

(3) Equipments are expensive.

For the reasons stated above, if cryogen-free dilution refrigerators that can be operated easily and automatically for allowing general users to use them are developed, it is expected that dilution refrigerators will come to be used more widely.

2.Operation principles of dilution refrigerators

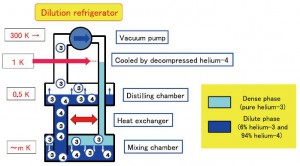

(1) Figure 1 illustrates a conceptual diagram of the dilution refrigerator. When liquid mixture of 3He and 4He is cooled below 0.8 K, mixture separate into two phases: a 3He dense phase (almost pure 3He) and a dilute phase (in which approximately 6% of 3He is diluted into 4He). The 3He dense phase is lighter, and floats on the dilute phase.

(2) When temperature of the distilling chamber is stabilized to approximately 0.5 K, only 3He will evaporate selectively due to the difference in the vapor pressure (fractional distillation). When 3He is vaporized in the distilling chamber, the concentration difference of 3He in the dilute phase between the distilling chamber and the mixing chamber will be arise. and 3He will move upward due to the osmotic pressure from the mixing chamber to the distilling chamber. To compensate for 3He evaporated in the distilling chamber, 3He in the dense phase at the mixing chamber will merge into the dilute phase

(3) When 3He is forced to solve from the dense phase into the dilute phase, refrigeration power will be generate. This process is called dilution, so refrigerators using this process are called dilution refrigerators.

The liquid 4He at 0.5 K or lower temperatures has zero viscosity (superfluidity). 3He in the dilute phase can be regarded as a “gas” that can freely

move in the superfluid 4He. Meanwhile, 3He in the dense phase can be regarded as a “liquid” state in which interaction of the 3He is strong . Therefore, the dilution process can be regarded as a process in which the liquid state 3He evaporates to gas state 3He. The refrigeration capacity produced in this process is correspond to the latent heat of vaporization.

(4) The 3He evaporated in the distilling chamber is discharged and compressed by an external vacuum pump and returned to the cryostat again. After that, in a conventional dilution refrigerator, 3He gas is cooled down to 1K and liquefied with depressurized liquid 4He (precooling). The liquefied 3He is further cooled through the heat exchanger and returns to the mixing chamber.

(5) As described above, 3He circulates in dilution refrigerators and generates cooling power continuously.

Dilution refrigerators can generate low temperatures from 1 K to several mK, have been widely used for measurement of physical properties, but currently less used in other area. The main problems are the equipment is large, liquid helium needs to be refill periodically, and especially the operation procedures to handle the dilution refrigerators are complicated, which makes it impossible for general users to handle the dilution refrigerators.

As a solution to solve all these problems at once, cryogen- free dilution refrigerators with mechanical refrigerators in place of liquid helium have been developed.

3.Cryogen-free dilution refrigerators

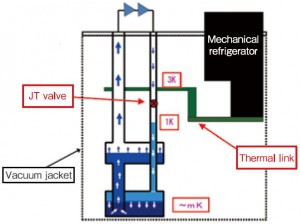

Figure 2 illustrates the schematic diagram of the cryogen-free dilution refrigerator. In the cryogen-free dilution refrigerator, the circulating 3He gas is cooled to approximately 3 K with a mechanical refrigerator (4K-GM refrigerator or 4 K pulse tube refrigerator). Then the 3He gas undergoes Joule-Thomson expansion with the JT valve and liquefies.

The advantages of cryogen-free dilution refrigerators are listed below.

(1) Easy operation (controlled automatically with computers), reduces the physical and mental burdens on researchers and allows easily operation on operators who do not have much experience.

(2) They can be made to be ultra-compact.

(3) It does not consume liquid helium (addressing the helium resource problem).

Meanwhile, the disadvantages are that efficiency is worse than conventional dilution refrigerators and mechanical refrigerators generate vibrations. Conventional dilution refrigerators can cool to minimum temperature of 2 mK, but cryogen-free dilution refrigerators can achieve only 10 mK range (refer to Chapter 5 to find out the reason).