This post is also available in: Japanese

4. Integrated cryogen-free dilution refrigerators(combined with mechanical refrigerators for precooling)

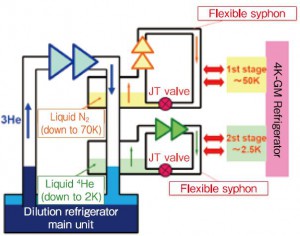

We developed and improved integrated cryogen-free dilution refrigerators from 2007 to 2010. The structure of the integrated cryogen-free dilution refrigerator is such that the 4 K pulse tube refrigerator (PDX-05 made by Iwatani Industrial Gases Corporation (0.5 W@4.2 K)) is thermally contacted with the dilution refrigerator main unit directly, as a way to precool the circulating 3He gas to cool down to temperature of 50 K with the first stage of the 4 K pulse tube refrigerator, then to temperature of 3 K with the second stage of the 4 K pulse tube refrigerator.

And then 3He gas undergoes Joule-Thomson expansion with the JT valve to cool and liquefy 3He (Figure 3). 4 K pulse tube refrigerator have no pistons or other moving parts compared to 4K-GM refrigerator, so they have an advantage in the vibrations caused by the refrigerator are smaller.

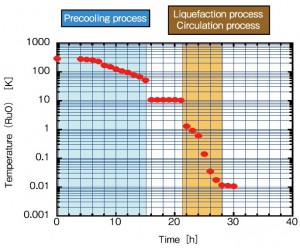

Figure 4 shows the example of the cooling processes of the integrated cryogen-free dilution refrigerator. The refrigerator went through a precooling process, liquefaction process, and circulating process. And then it stabilized after approximately 30 hours passed. In figure 4, temperature hold constant at around 10 K for the waiting time of the control program, so it can be eliminated by changing the program setting. The minimum temperature of the integrated cryogen-free dilution refrigerator obtained in improvement test was 4.5 mK. The refrigeration capacity was 100 μW at 100 mK.

Microvibrations of the pulse tube refrigerator in integrated cryogen-free dilution refrigerator are propagated to the dilution refrigerator main unit. It was found that the micovibrations of the pulse tube refrigerator significantly affect the temperature of the mixing chambers at the temperature of the integrated cryogen-free dilution refrigerator is 10 mK or lower. In addition, the manufacture of the 4 K pulse tube refrigerator (PDX-05) was practically discontinued because the production cost was so high. Then we change the design to use 4K-GM refrigerator. And we separate the mechanical refrigerators from the main unit of dilution refrigerator to completely prevent the vibration from the 4K-GM refrigerator. We started developing separated dilution refrigerator in 2011.

5.Separated dilution refrigerators

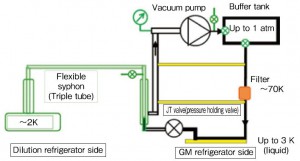

In the separated dilution refrigerator, the 4K-GM refrigerator (HE10 made by Iwatani Industrial Gases Corporation (1.0 W@4.2 K)) is used. The 4K-GM refrigerator is completely separate from the dilution refrigerator main unit. Flexible siphons are used to connect them and liquid nitrogen and liquid helium-4 liquefied with the 4K-GM refrigerator are transferred to the dilution refrigerator main unit for precool the circulating gas. The echanical refrigerator can be separated from the dilution refrigerator main unit, so the vibrations of the GM refrigerator are not transferred to the main unit.

The structure of the second stage flexible siphon in which liquid 4He circulates is as shown below. The 4He gas at atmospheric pressure is cooled by the 4K-GM refrigerator until liquefied at approximately 3 K. Then 4He isfurther cooled by the JT valve. The flexible siphon has two paths̶back and forth̶for the liquid helium-4. Liquid 4He is transported to the cryostat of the dilution refrigerator to cool the dilution refrigerator and then returns

to the cryostat of the GM refrigerator, being circulated by the vacuum pump.

Vibrations at the mixing chambers of the integrated dilution refrigerator and the separated dilution refrigerator were measured and compared. The vibrations of the integrated dilution refrigerator with the pulse tube refrigerator were approximately 7 μm. The vibrations of the separated dilution refrigerator were able to be reduced to 2 μm or less. The separated dilution refrigerator uses GM refrigerators, the vibrations of GM refrigerator are large, but the flexible siphons shut out most of the vibrations.

However, the minimum temperature of the separated dilution refrigerator was 50 mK, proving inferior to the integrated dilution refrigerator. This is because the heat exchanger efficiency was worse in separating units and flexible siphons cause increasing heat input.

6.Summary and assignment

We have developed two types of cryogen-free dilution refrigerators: the integrated type and separated type. We have succeeded in achieving a minimum temperature of 4 mK for the integrated cryogen-free dilution refrigerator; nearly a world record for cryogen-free dilution refrigerators.

We intended to improve the performance of separated cryogen-free dilution refrigerator, but the temperature was slightly inferior due to the reduction in the heat exchanger efficiency. We tried to improve the flexible siphons, but could not significantly improve them, so the minimum temperature remained at 45 mK.

The price of 3He gas becomes a problem in terms of cost for dilution refrigerators. The price of 1 L of 3He gas at atmospheric pressure was several tens of thousands of yen when we first developed the dilution refrigerators, but the price temporarily surged to more than half a million yen. It remains at around 400 thousand yen recently.

Our new development objectives are to create refrigerators that reach 80 to 100 mK, temperatures used for general purposes, and smaller and less expensive units. Specifically, we will aim at reducing the overall costs: the volume of 3He gas used will be significantly reduced compared to prior models and the smaller and less expensive HE05 (0.5 W@4.2 K) will be used as the 4K-GM refrigerator.

Moreover, we will pursue even greater ease of use.

We have been developing new models with the goals listed below in order to arouse demand from new users who have not used cryogen-free dilution refrigerators.

– Refrigerators that can be programmed to operate completely automatically for long hours.

– Refrigerators that do not require operation of valves and adjustment of the mixed quantity of 3He and 4He in the cooling process.

– Reduction of the cooling time from room temperature.

– The smallest size and lowest prices.

Finally, photographs of the 4 K refrigerators used for cryogen-free dilution refrigerators are shown in Figure 7. From the left, the 4 K pulse tube refrigerator (PDX-05) and 4K-GM refrigerators (HE10 and HE05).

*This article was released in “Technical Journal No.79 published in June, 2015”

Joint Development of Cryogen Free Dilution Refrigerator using 4K-Cryocooler Tomio NISHITANI*1 and Tohru HATA*2

*1 Cryogenic Equipment Division, Ulvac Cryogenics Inc. 60 Ujihinojiri, Uji, Kyoto, 611-0021, Japan

*2 Ultra Low Temperature Laboratory, Graduate School of Science, Osaka City University. 3-3-138 Sugimoto, Sumiyoshi-ku Osaka, Osaka 558-8585, Japan

Cryogenic Equipment Division of Iwatani Industrial Gases Corporation (IIG), which produces and selles cryogenic refrigerators and their application products, was transferred to Ulvac Cryogenics Incorporated on May 1, 2014. Cryogenic Equipment Division of IIG and Osaka City University jointly developed cryogen- free dilution refrigerator from 2006 to

20131)–5). From 2014, Ulvac Cryogenics Incorporated has succeeded this effort and has been developing a new dilution refrigerator with Osaka City University This paper reports the history and progress of these development efforts.

Acknowledgments

The cryogen-free dilution refrigerators introduced in this paper were developed in cooperation with Osaka City University’s Ultra Low Temperature Group. We offer cordial thanks to Osamu Ishikawa, Hideo Yano, and Ken Obara.

References

1) T. Hata, T. Nishitani, S. Togitani, A. Handa, K. Obara:Development of New Type Dilution Refrigerator Using Pulse Tube, 137.

2) T. Hata: Dilution Refrigerator without Refrigerant, Journal of the Cryogenic Association of Japan No.2 (2008), 44.

3) A. Handa, S. Togitani, T. Nishitani, K. Obara, H. Yano, O. Ishikawa, T. Hata, Dilution Refrigerator without Refrigerant, Collected Abstracts of Cryogenic and Superconductivity Society of Japan (Autumn 2009), 33.

4) A. Yamaguchi, K. Obara, H. Yano, O. Ishikawa, T.Hata, A. Handa, S. Togitani, and T. Nishitani, Development of Dry Dilution Refrigerator and

Temperature Measurement with Quartz Tuning Fork. Proceedings of Low Temperature Physics, (2011), 26.

5) T. Hata, T. Matsumoto, K. Obara, H. Yano, O. Ishikawa, A. Handa, S. Togitani and T. Nishitani, Development and Comparison of Two Types of

Cryogen-Free Dilution Refrigerator. Journal of Low Temperature Physics Vol.175 (2014), 471-479.