News Category

Notice concerning sign agreement for "Analysis Loan for ESG/SDGs Promotion" with Sumitomo Mitsui Banking Corporation

ULVAC, Inc. (headquartered in Chigasaki City, Kanagawa Prefecture; President: Setsuo Iwashita; hereinafter "the Company") announces that it has signed an agreement with Sumitomo Mitsui Banking Corporation (President and CEO: Akihiro Fukutome) for "ESG/SDGs Promotion Analysis Loan".

The "ESG/SDGs Promotion Analysis Loan" is a loan product that evaluates a company's initiatives and information disclosure on ESG aspects and its contribution to achieving the SDGs (Sustainable Development Goals) based on original evaluation standards developed by Sumitomo Mitsui Banking Corporation and The Japan Research Institute, Limited (President: Katsuyuki Tanizaki). The loan product provides an analysis of the current status of the appropriateness of initiatives and information disclosure, future issues, and examples of initiatives to address these issues.

The results of this evaluation of our company were judged to be of a very high standard in "Climate Change Responsiveness," "Customer Integrity," and "Sustainability Management".

The company has been judged to have implemented excellent ESG initiatives and information disclosure in its corporate management, and to have a high level of willingness to contribute to the SDGs through its business activities.

In terms of ESG initiatives and information disclosure, the following points were evaluated as advanced.

- The company has set medium- and long-term greenhouse gas emission reduction targets for its business activities of 40% reduction by 2030 (compared to 2020) and virtually zero by 2050 and has introduced renewable energy and energy-saving initiatives at its business sites. In addition, the company is contributing to the reduction of its customers' environmental impact by improving the efficiency of power devices and saving energy in various electronic devices through technological innovation in vacuum technology.

- In addition to activities to verify required safety quality at the drawing stage and product shipment stage, the company is striving to improve customer satisfaction through efforts to enhance the quality of its products and services based on a quality management system in accordance with the ISO 9001 standard. In addition, the company contributes to the promotion of a smart society and digitalization by providing a variety of devices, as well as by improving the compactness, capacity, and safety of batteries for electric vehicles (EVs) through the use of its thin-film deposition technology.

- The company has established a company-wide sustainability promotion system through the establishment of the Sustainability Promotion Committee and the Sustainable Management Promotion Office and has strengthened its commitment to sustainability through its core business by setting "creation and co-creation of innovation centered on vacuum technology" and "contribution to a sustainable global environment" as Materiality (important issues). The company is strengthening its commitment to sustainability through its core business.

In addition, the committee also recognized the company's ambition to achieve Goal 9: "Create a foundation for industry and technological innovation" and other SDGs through its business activities.

Based on the company's basic management philosophy of "Contribute to the development of industries and science by comprehensively utilizing its vacuum and peripheral technologies," the company will pursue cutting-edge technologies in vacuum technology with its partners and contribute to the creation of a sustainable society while fulfilling the social responsibilities.

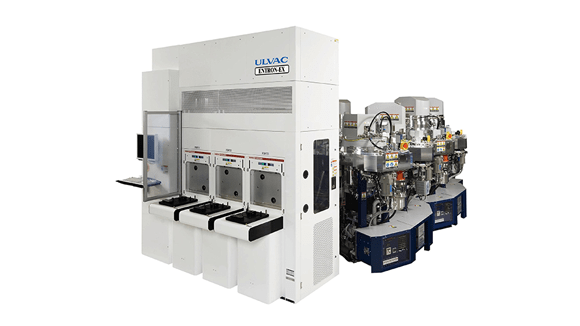

Multi-chamber sputtering system 「ENTRON™-EX W300」

The multi-chamber sputtering system "ENTRON™-EX W300" has a smaller footprint (equipment area) and meets ULVAC Corporation's original standards for environmental friendliness: "space saving, smaller size, lighter weight, simplification," and "reduced number of parts," which are expected to save resources and reduce CO2 emissions during customer manufacturing.

uGmni-200 single-wafer composite module-type deposition processing system

The "uGmni-200" (uGemini) series is a film deposition processing system that incorporates several different process modules such as sputtering, etching, ashing, and CVD on the same transport core, based on the concept of common component parts. Assembly time has been improved by more than 10% compared to the previous model by improving assembly navigation and optimizing the layout.

For further information

ULVAC, Inc. web_info