This post is also available in: Japanese

Expanding Market Acceptance of ULVAC Products and Technologies to Meet R&D, Pilot Production and High Volume Manufacturing Needs

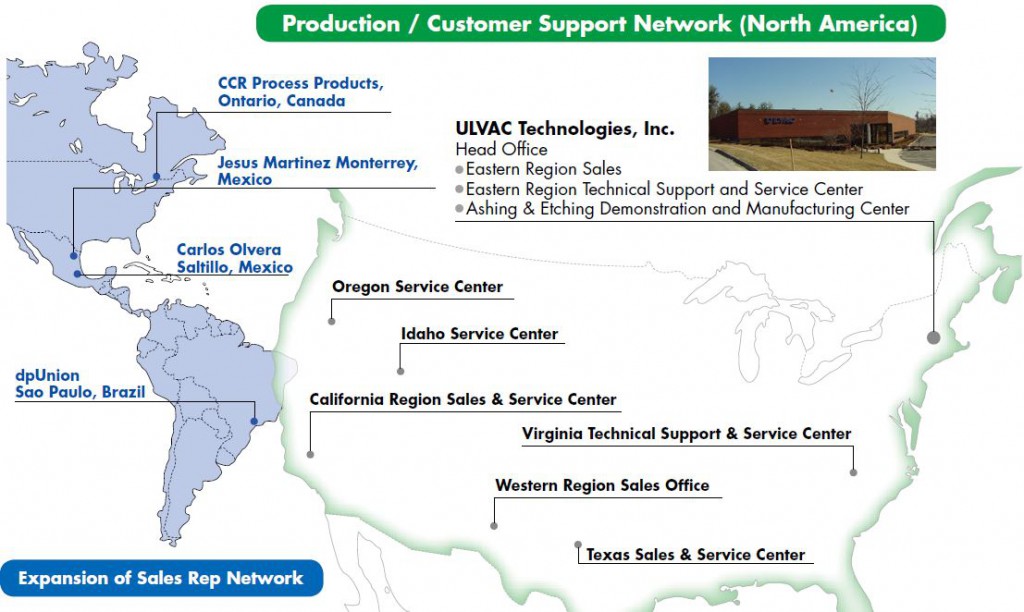

As key areas of ULVAC operations, North America and the emerging Latin America territories comprise a diverse set of markets that align with ULVAC’s broad spectrum of vacuum-based technologies. These markets include next-generation memory and logic devices, TFB, PV applications, biomedical applications, MEMS devices, LED, EC glass, automotive, refrigeration/air conditioning, and many others. Within each of these markets there is a manufacturing sequence that ranges from R&D, to pilot production, to HVM (High Volume Manufacturing) in most cases. UTECH’s mission is to evaluate the needs of these markets, and introduce the customers to the advantages of ULVAC products, both imported and domestically manufactured.

An Introduction to ULVAC Technologies

When you think about it, if you consider the number of ULVAC manufacturing divisions, multiplied by the products of each, we are left with a wide matrix of product offerings and the challenge becomes, how do we support such a spectrum? The answer is that we are fortunate to have a workforce with many, long-term employees that possess a wide-range of product knowledge. At one point in time, UTECH employed 130 people. After the unfortunate events of 9/11/01, we were faced with a significant business downturn and as a result, reduced the size of our workforce by > 50%. However, today as a 55 employee company, we find ourselves leaner but more versatile and efficient than ever. Much like the 2013 World Series Champion Boston Red Sox, our success is built on a diverse, dedicated workforce willing to “play” multiple positions within the company as needs arise. I am proud to say that our teamwork has been and will continue to be vital to our success!

In our interview with the President Wayne Anderson, this issue of “Visiting ULVAC” will provide you with insight into the UTECH history, markets served, business philosophy and a brief look into the future.

A Brief History Lesson

ULVAC Technologies, Inc. (UTECH) was established on March 31, 1992 in Andover, Massachusetts in response to ULVAC, Japan’s desire to globalize and create a Western Operations. However, ULVAC’s roots in the United States pre-date this event in (2) locations: 1) At ULVAC North America Corporation based in Kennebunk, Maine which served as a distribution center for ULVAC products and a low volume/custom equipment manufacturer and 2) as part of a joint venture with BTU Engineering, Inc. in Billerica, Massachusetts; whereby diffusion furnace products/technologies (BTU) were exchanged with selective tungsten deposition systems (ULVAC ERA-1000). These (2) entities were dissolved upon the establishment of UTECH.

Prior to the establishment of UTECH in the 1980’s, ULVAC acquired today’s ENVIRO-based ashing technology from Emergent Technologies based in Connecticut. This company was owned by our old friend Dick Bersin. After the acquisition, process and product development continued in Japan for several years under the direction of Dick. These efforts ultimately lead to the introduction of the UNA-model ashing system, which was installed primarily, in Japan.

This product was eventually transferred to UTECH and became the basis for our local manufacturing operation. Local manufacturing of the UNA transitioned from the initial “knock-down kit” approach, to 100% domestic sourced parts; whereby the product name was changed to “Phoenix”. The product name has since been changed to “ENVIRO”, to leverage its environmentally friendly solvent-free processing capability.

Market acceptance of our new product began to take hold in the mid-1990’s, which created the need for UTECH to move to a facility that was more conducive to semiconductor equipment manufacturing.

As a result, in 1997, UTECH engaged a construction firm to design and build a new 42,000 ft2 semiconductor-grade facility that is our home today in Methuen, Massachusetts. Our facility offers a Class- 10/100 demonstration laboratory to support ashing and etching technologies along with Class-1000/10,000 clean manufacturing space.

Over the years, our certified business operations at UTECH have grown to be quite widespread and offer a challenging work environment for our (55) member team, including a:

1) Center for sales and service for Import Products including systems and components into the North American and Latin American markets.

2) Center for the ENVIRO ashing product line including R&D, manufacturing, sales and service.

3) Center for ULVAC’s etch technology penetration into the North American market.