This post is also available in: Japanese

Quality and High Sound Quality Realized by Using Sputtering Film

Reduced Abrasion, Good Heat Conductivity, and Static Electricity Prevention Through the Use of Vacuum Film Technologies

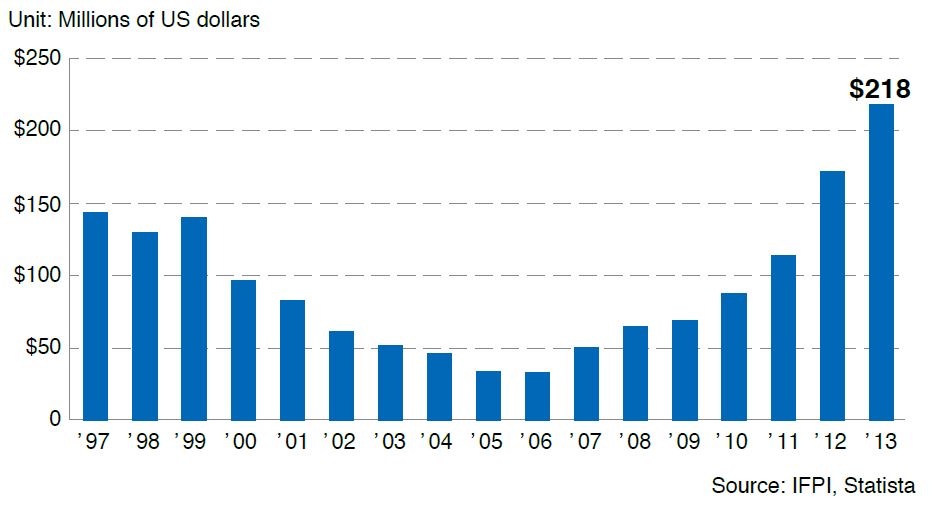

Vinyl records quickly lost their long-held dominant position in the music publishing market when digital CDs made their debut at the beginning of the 1980s, and in just a few short years they had been relegated to a small corner of the music publishing market. Vinyl records did not completely disappear, however; they were still produced for a small number of audio fans. In recent years, demand for vinyl records has tended to increase, mainly among the younger generation who were brought up listening to CDs. The main reasons behind this trend include the fact that CD sleeves don’t have the same dynamic feel as vinyl record sleeves do and that the high sound quality that is unique to analog recording is only reproducible with today’s high performance audio sets. Although the performance of acoustic products has been increasingly enhanced, the original quality of polyvinyl chloride (PVC) —or “vinyl”— LP records has not been modified or improved since they made their debut in the latter half of the 1940s. For this issue of LIVING & ULVAC directs a spotlight on the high-quality PROLAYER records created by ULVAC TAIWAN INC. PROLAYER records are produced by leveraging vacuum technologies to eliminate the weakness of vinyl records, thereby providing even higher sound quality.

Interview with: ULVAC TAIWAN INC.

PROLAYER Records Produced Using Vacuum Technologies

ULVAC TAIWAN INC. (UTI; head office: Hsinchu city, Taiwan) was founded in 1981. It is a core overseas member of the group of companies that act as ULVAC’s global production base.

UTI’s main line of business is the manufacture of vacuum equipment for the electronics industry, which produces devices such as semiconductors and LCD televisions, and it also provides field supports for this industry. As part of its unique range of activities, the company has recently developed PROLAYER, a groundbreaking sputtering film record that is made using a type of thin-film deposition equipment called a sputtering system.

Universal Resurgence of Interest in Vinyl Records

The world’s first vinyl record was the 78 rpm shellac record.

It had a recording time of about five minutes on one side. Some time later, the use of high-density polyvinyl chloride (PVC) allowed extremely narrow grooves to be formed in records to act as the sound source. As a result, the long-playing (LP) record, which can hold 30 minutes or more of music on one side, became the principal type of vinyl record.

The LP record was developed in the latter half of the 1940s, and it replaced conventional 78 rpm records from the 1950s onwards. Until the digital CD appeared in the early 1980s, LP records were the main form of music media for about half a century. In the 1990s, vinyl records became temporarily obsolete.

Since the mid-2000s, however, LP record production has been gradually increasing, and they have regained some of their popularity through support from not only vinyl fans, but also the younger generation.

A Radical Measure to Improve Previously Unchanged Vinyl Records

Throughout the vinyl record age and the digital CD age, audio electronic devices —such as record players, CD players, amplifiers, and speakers— have undergone an amazing evolution, thereby contributing to the high-quality sound we now enjoy. In contrast, the materials and production process used for vinyl records have remained unchanged, so vinyl records have not evolved in the same way as audio devices have.

So, is the vinyl record a perfect product? No. Vinyl recordshave a lot of problems. The main problems are as follows. A record differs from a CD in that sound is produced by a phonograph needle tracing the record’s grooves. The heat generated on the side in contact with the needle causes the record’s shape

to change, which eventually results in damage to the grooves.

Consequently, the service life of a record is limited. Another crucial issue is a problem with the material PVC. PVC tends to generate static electricity, which results in dust accumulating on the record. This dust generates noise and disturbs the comfortable sound of the music.

Eliminating Problems with Records through the Use of Sputtering Film

Vinyl records have the following drawbacks: they are inferior in terms of abrasion; they have very low heat conductivity; and they tend to generate static electricity. As a fan of vinyl, Clare Wei (UTI Vice president) wondered whether vacuum technologies could be leveraged to eliminate these problems. He then had a flash of inspiration when he came up with the idea of applying a vacuum thin film to the surface of a phonographic record.

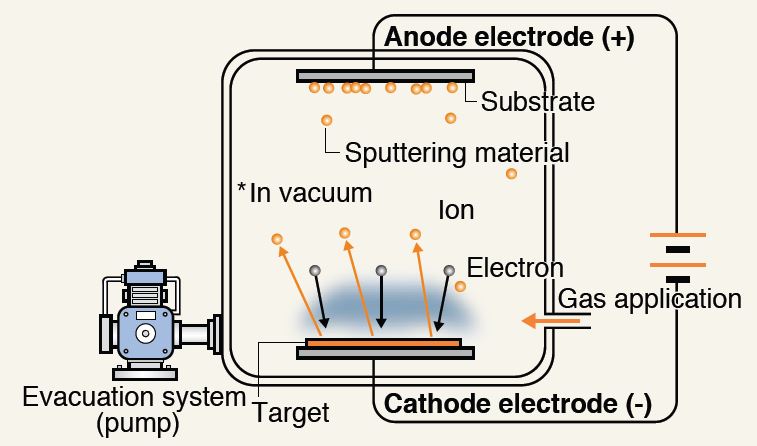

Various different methods can be used to form a thin film with the aid of a vacuum. The following are the three most commonly used ones: the evaporation method, which is relatively easy to use for a wide variety of applications; the sputtering method, which is suitable for large homogeneous areas; and the vapor phase growth method, which forms a high-performance chemical thin film through vaporization. After some trial and error, it was finally determined that a molybdenum sputtering film formed with a sputtering system would eliminate the problems.

This sputtering film enhances vinyl records by molybdenum’se melting point up to more than 2,500°C, thereby increasing the surface hardness to about 30 times greater than conventional vinyl records material, PVC, and increasing the heat conductivity to about

1,300 times greater. In addition, since the sputtering film produces a smooth surface, the friction force is reduced by 50% or more, and the damage caused by the pressure that the stylus exerts on the grooves is markedly reduced. It has been demonstrated that the sputtering film contributes to an increased service life for records.

In the spring of 2015, Clare Wei approached Mr. Yu-Chang Huang, a chief member of the Kaohsiung Electrical Commercial Association, with his idea, and together they launched a joint development project. In August 2015, the sputtering film record was exhibited at the TAA Taipei Yuen-shan Audio Show. An audio commentator was invited to attend the show, and Ms. Artemis H.R. Yen who granted the Post-Graduated diploma in piano Performance from the famed Moscow State conservatory, performed one of Tchaikovsky’s piano pieces live. After that, an event was held where those attending listened to the same piece of music being played using a conventional vinyl record and a sputtering film record to compare the sound quality. The sputtering film record received such a favorable review from the audio commentator that it actually is our expectations.

We are now in the process of trademarking the sputtering film record, and the mass production of sputtering film is almost within sight. Going forward, we will develop concrete approaches for promoting sales of the PROLAYER record by selecting target artists and album music for its world debut.

ULVAC TAIWAN INC.

優貝克科技股份有限公司

http://www.ulvac.com.tw(中国語繁体字サイト)