This post is also available in: Japanese Chinese (Simplified)

Introducing the dry etching technology required for the optical waveguide process.

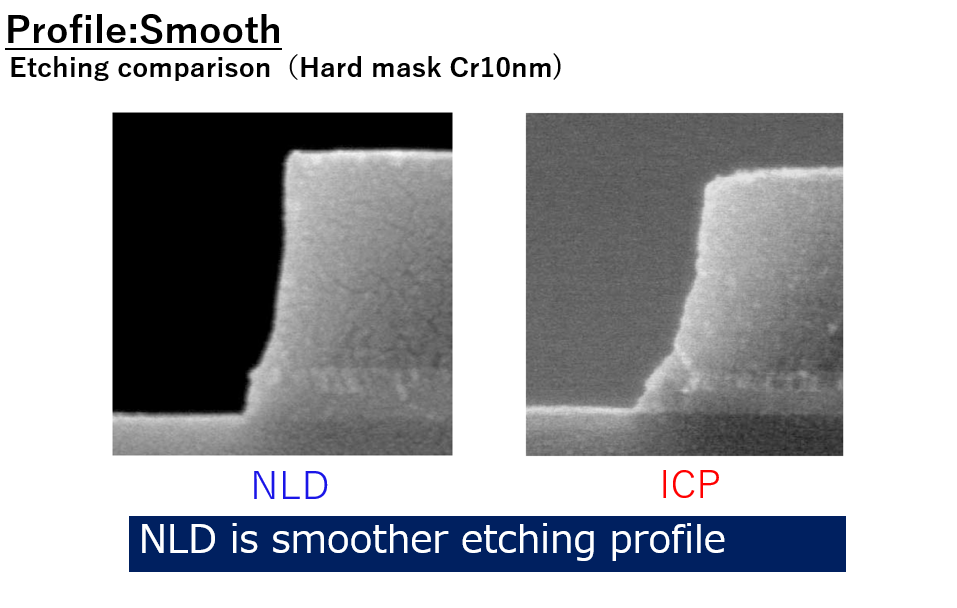

Waveguide hard mask etching

Hard masks (Ni, Cr) can be processed with ULVAC’s unique low-voltage, low-electron temperature, high-density plasma magnetic neutral line plasma (NLD).

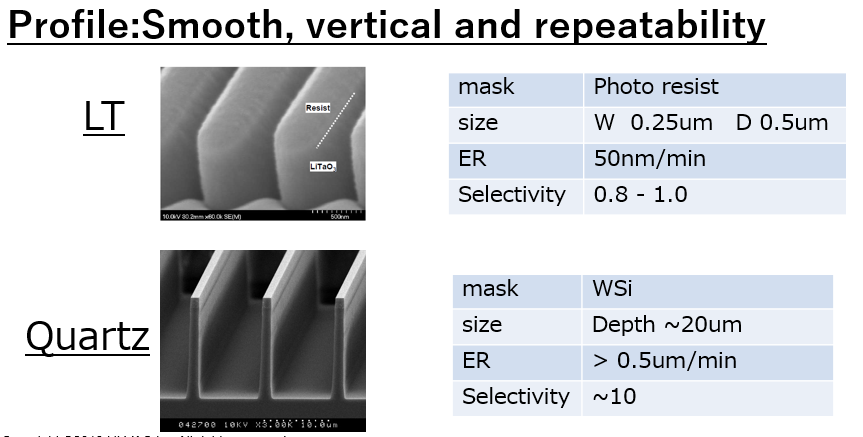

LN, LT, InP Waveguide etching

In the case of optical waveguides, fluctuations in verticality and side wall smoothness or core width increase the propagation loss of the optical beam. The side walls of the core should be smooth and the width of the core should be kept uniform. Since quartz and the like are etched by CF-based ion impact, low-pressure, high-density plasma is ideal. Magnetic neutral wire plasma (NLD) is effective for machining waveguides because of its low voltage, low electron temperature, and high density plasma.