This post is also available in: Japanese Chinese (Simplified)

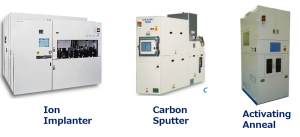

We provide a process that enables high-energy injection and high-temperature and low-temperature injection. We can also provide carbon cap technology that prevents substrate roughness due to Si evaporation during activation annealing.

Challenges

Both high-concentration and low-concentration injection

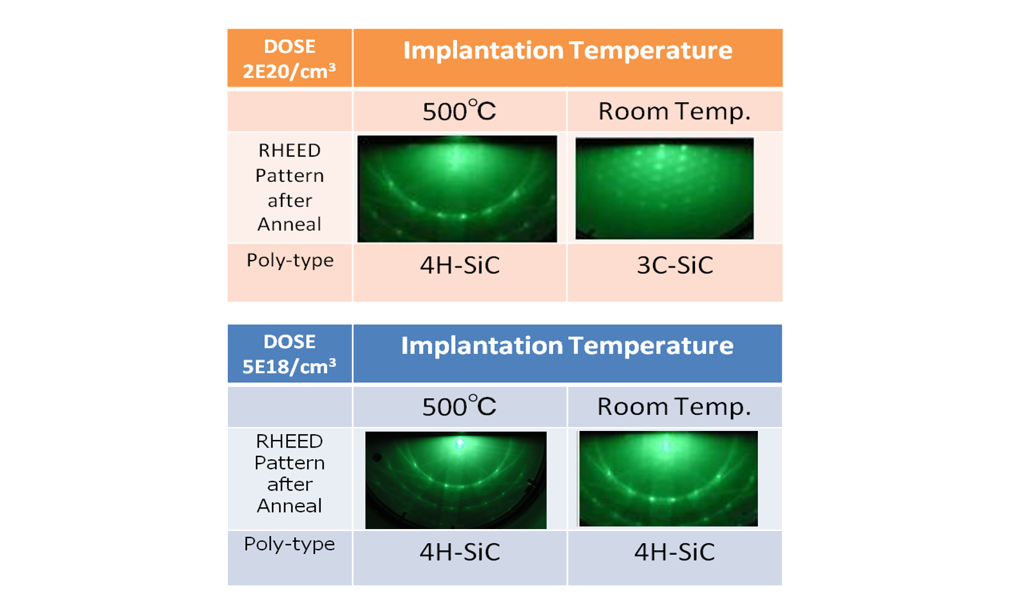

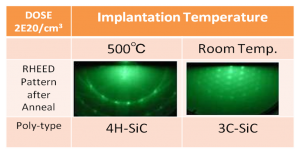

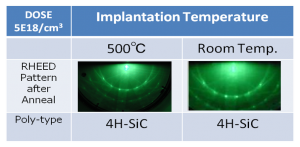

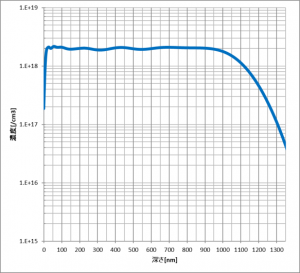

When SiC is injected at a high concentration, crystal defects occur and cannot be recovered by annealing, so treatment at high temperature is required. On the other hand, it is known that normal temperature injection has better characteristics for low concentration injection.

SiC thermal diffusion

Since SiC is difficult to diffuse heat, higher energy is required to inject it deeper.

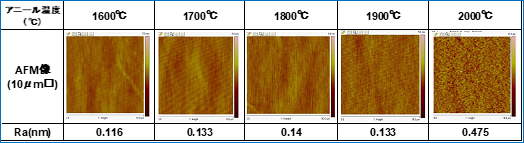

Rough surface due to high temperature process

Since the activation temperature of SiC is 1600 to 1800 ° C, Si loss occurs and causes the problem of surface roughness.

Solutions

high-concentration and low-concentration injection

Equipped with Dual Platen that can instantly switch between high temperature 600 ℃ and normal temperature injection, achieving high throughput. High-temperature processing realizes process stability and transfer reliability at high temperatures by ULVAC’s original substrate temperature rise method.

High energy injection

Covers energy from 10kV to 1.2MeV and can support a wide process range

SOne solution for high temperature process of SIC

ULVAC can provide total solution including Ion implantation, carbon cap, annealing process