This post is also available in: Japanese

The automotive industry has been experiencing great changes recently. Until now, the industry has been focused on the comfort and convenience of cars. However, as a result of concerns about global warming caused by CO2 and the increasing incidence of accidents caused by older drivers, the focus is shifting to reducing environmental impacts and increasing safety.

For these reasons, development of plug-in hybrid electric vehicles (PHEVs), electric vehicles (EVs), and fuel cell vehicles (FCVs) is underway in countries around the world. An important consideration for the various on-board parts is power electronics, represented by such components as the power control units (PCUs) that control batteries and motors.

*This article appeared in the September 2019 issue of the technical journal No. 83.

Application of power electronics and power devices

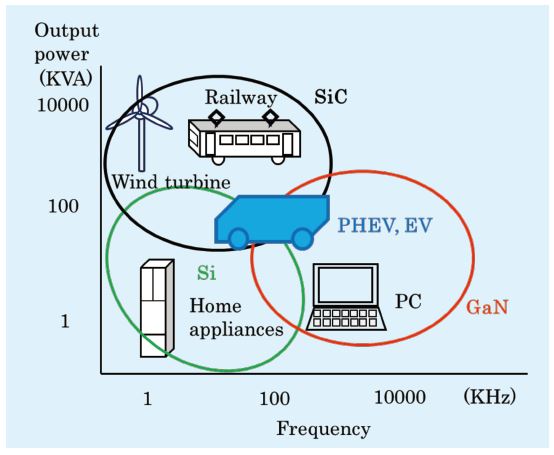

Power electronics is a technology that converts AC and DC into forms most suitable to various instruments, and, as shown in Figure 1, is widely used in automobiles and home appliances. As the automobile industry transitions MOSFET from gasoline-powered vehicles to PHEVs and EVs, PCUs are needed to ensure proper mutual power conversion between batteries and motors. Insulated gate bipolar transistors (IGBTs) are being used for PCUs. Metal oxide semiconductor field effect transistors (MOSFETs) and IGBTs are being used as the mainstay power devices because they offer a high cost-performance ratio, desirable functions, and high performance, and their drive circuits are simple and do not break easily.

MOSFETs are ideal for small-capacity, high-speed applications. An IGBT has a device structure in which a p+ layer is added to the drain side of a MOSFET; this is ideal for large-current, high-voltage applications. To improve the characteristics of IGBTs, technologies are being developed to achieve a miniaturized gate structure and use of thinner wafers. Additionally, to reduce cost, some manufacturers have begun to increase the diameter of thin wafers (from 200 mm to 300 mm).

Materials for Power Devices

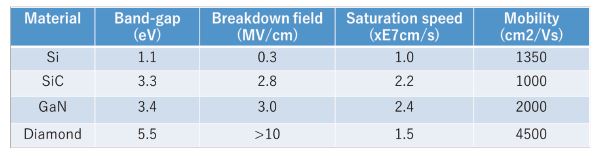

Typical substrates for power devices include Si, SiC, and GaN. Currently, the mainstream material for power devices is Si, and many Si-MOSFET and Si-IGBT products are in use. Si’s greatest advantage is its low wafer cost. The cost of an Si wafer is in the range of several thousand to tens of thousands of yen per wafer, whereas the cost of an SiC wafer is higher, starting at tens of thousands of yen.

A GaN wafer is even more expensive, costing hundreds of thousands of yen for the 2‑inch size. However, there is high expectation for Sic, GaN, and diamond as next-generation power device materials because they possess a wide band gap, high dielectric voltage, and high electron mobility, as shown in Table 1.

You can download full article with your registration

https://www.ulvac.co.jp/r_d/technical_journal/tj83j/