This post is also available in: Japanese

Safe thin-film batteries that experience almost no degradation due to repeated charging and discharging

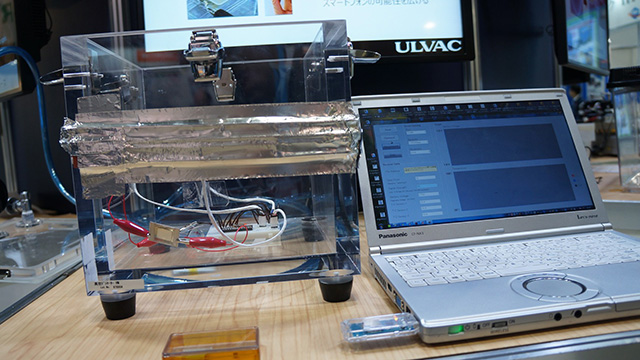

Demonstration (2) presented an example application for the thin-film solid-state battery, which has attracted attention as a battery technology that could be used with the mobile devices of the future. For this demonstration, a temperature sensor and a wireless communication module (the ZigBee module) were operated using a thin-film solid-state battery, and the measurements obtained from the temperature sensor were transmitted wirelessly.

The lithium-ion batteries that are used in modern-day smartphones and tablets contain a liquid called an “electrolytic solution.” The problems associated with the use of lithium-ion batteries include the fact that repeated charging and discharging causes their charging capacity to degrade and that, if they are bent or subjected to impact, the electrolytic solution may leak, thereby causing a fire.

In contrast, solid-state batteries—which use a solid electrolyte instead of an electrolytic solution—exhibit almost no degradation due to repeated charging and discharging and they do not leak in the same way as an electrolytic solution does. One additional advantage is that thin-film solid-state batteries can be bent.

At the exhibition booth, it was demonstrated that an experimentally manufactured thin-film battery operates normally under reduced pressure. Under this condition, the electrolytic solution used in standard lithium-ion batteries may leak, thereby leading to an accident. This demonstration confirmed that the thin-film battery, which is a type of solid-state battery, does not cause such accidents.

Detecting biomagnetism without using expensive magnetic shielding

Demonstration (3) verified that weak magnetism generated by a living body can be easily measured by using a tunneling magnetoresistance (TMR) element, which is a type of highly sensitive magnetometric sensor. The sensor detected weak magnetism generated by moving pulse waves.

It has long been known that the cell-level activities of living bodies generate weak magnetism. It was expected that measurement of this biomagnetic field could be used for health care and medical treatment. However, the magnetism generated by living bodies is very weak, and an ultrasensitive magnetometric sensor is required to measure such magnetism.

At present, only a SQUID magnetometric sensor, which is based on the concept of superconductivity, can be used in practice to measure biomagnetic fields. SQUID magnetometric sensors must be placed in a cryogenic environment to maintain them in a superconductive state. This cryogenic environment can be achieved only through the use of liquid helium, which is expensive.

In addition, the magnetic field generated by the Earth (geomagnetism) and the magnetism existing in the environment (i.e. magnetism generated by power cables for electric railways, electronic devices, etc.) are much stronger than the magnetic fields generated by living bodies. Therefore, biomagnetic fields are generally measured using a SQUID magnetometric sensor while such magnetism noise is blocked using an expensive magnetic shield.

However, if a tunneling magnetoresistance (TMR) element is used as a magnetometric sensor, measurements can be taken at room temperature without the sensor needing to be cooled. Given this, the need to purchase expensive liquid helium is eliminated. In addition, since a magnetometric sensor can be positioned very close to a living body, weak biomagnetic fields can be measured without having to use an expensive magnetic shield. This type of magnetometric sensor has great potential for future applications.

This demonstration was performed in cooperation with the Ando Laboratory of Department of Applied Physics, School of Engineering, Tohoku University, and Radix, a venture business that was founded on the basis of an idea produced by Tohoku University. The tunneling magnetoresistance element was manufactured using an ULVAC production system.

A high-performance material whose electric resistance changes significantly in response to the temperature

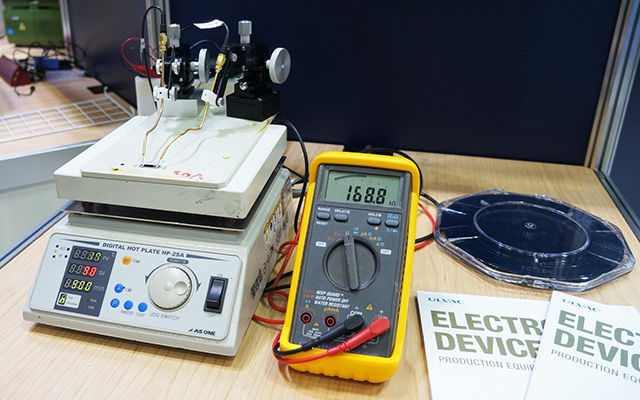

The presentation in Demonstration (4) was related to a field that ULVAC specializes in: high-performance materials. A thin film of a high-performance material—vanadium oxide (VO2)—was placed and heated on a hot plate. Vanadium oxide has a relatively high resistivity at room temperature, but if heated, it loses resistivity by an amount equal to approximately four orders of magnitude when it reaches about 80°C.

ULVAC is planning to identify new applications, such as infrared cameras and temperature switches, by leveraging this characteristic of the resistivity changing significantly in response to the temperature.

This article has explained a few of the many possibilities offered by ULVAC technologies. These possibilities are likely to have given you a glimpse of the future for IoT. For further details, visit the ULVAC website, which provides detailed information on all of its products.

* This is an excerpt from an article that appeared in Mynavi news on April 11, 2016.

[Special edition] FINETECH JAPAN: State-of-the-art ULVAC technologies that support the IoT society [Japanese site]