This post is also available in: Japanese

Modules may be Further Integrated and Unified

Obinata: I was looking at 0.1 mm and 0.2 mm chips earlier in the lobby. While I was impressed, I was also thinking that if I sneezed I’d easily blow them all away. They are that small.

Obinata: I was looking at 0.1 mm and 0.2 mm chips earlier in the lobby. While I was impressed, I was also thinking that if I sneezed I’d easily blow them all away. They are that small.

Saito: How much smaller do you think they will get?

Sakai: Someone will give up someday, but we must believe that humans have unlimited intelligence. Well, it’ll stop somewhere though.

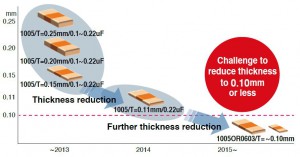

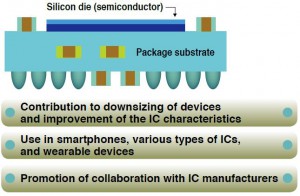

Saito: In the past, semiconductors were made on a large substrate and cut in small pieces. Now they are even smaller, and it is predicted that high-density packaging, in which a device is directly mounted on a substrate, will advance further in the future. How will miniaturization influence your products?

Sakai: Chips have been rectangular so far. In the future, “bending” or “odd shapes” may become the keywords.

Sakai: Chips have been rectangular so far. In the future, “bending” or “odd shapes” may become the keywords.

In terms of modules, we may receive a wide variety of requests from users who want to place them on an angled surface or in every available nook and cranny. The point of consideration will be how big a module should be to put together a selected range of functions.

Obinata: Sounds like we will need only one vendor in the future. It’ll give you more of an advantage.

Sakai: It is impossible to pack all necessary functions into a module. Roughly speaking, current smartphones have four parts: a CPU as a brain, an LCD for showing images, communication elements for interaction, and a battery to provide power. Some of these parts are analog and some are digital, so they cannot be completely integrated. Functions may be integrated within these four areas, however. This leads to a dramatic decrease in the number of modules while at the same time requiring further chip miniaturization.

Saito: Miniaturization is our strength. We will be happy to help you in many more areas in the future (laugh).

Speedy Responses to Promptly Meet Customer Needs

Obinata: Before finishing up, please let us know if you have any requests for us.

Sakai: That would be “speed.” Only speed generates money. Our company grew because of it. We were able to demonstrate the value of speed, which is usually difficult to measure, by meeting our customers’ requests. Speed makes a company better. Being fast is good.

Obinata: I completely agree. We must accelerate responses to customers as well as internal procedures.

Sakai: At Murata, requests for decisions are approved in as little as 2 to 3 days. This is a good result of delegating authority to make decisions to the employees.

It is like the company saying to the employees “Go ahead if you are in such a hurry!”

Obinata: One day I saw a document and was surprised with the number of seals of approvals. I made the employees halve the number of approvers. This tells me that we need a lot more improvement.

Sakai: Requests are checked more strictly when the economy is slow, of course. It is not that our employees are free to just do anything. I think it is that our executive officers doing a fine job of maintaining an exquisite balance between the two.

Obinata: We will use your stories as tips to accelerate our operations by giving employees more authority. We will continue learning from how Murata operates. Thank you for sharing these important stories and ideas.

Obinata & Saito: Thank you.

Mr.Norio Sakai

Fellow, Communication and Sensor Business Unit

Murata Manufacturing Co., Ltd.

Born on March 1, 1958. Graduated with a Master’s Degree from Kyoto University Graduate School of Engineering, Department of Mechanical Physical Engineering

1982 Joined the Production Engineering Division of Fukui Murata Manufacturing Co., Ltd. Developed manufacturing methods and equipment for multilayer ceramic capacitors and multilayer ceramic substrates.

1993 Joined the Yasu Division of Murata Manufacturing Co., Ltd.

2005 Took office as General Manager of the Package Engineering, Communication Business Unit.

2008 Also took office as General Manager of the 1st Manufacturing and Materials Engineering Division of

the New Product Unit.

2012 Took office as a Research Fellow.

2014 Also took office as General Manager of the Functional Board Product Division of the Communication Business Unit and Director of the Engineering Group of the Communication Business Unit.

Company Overview (as of March 31, 2015)

Company Overview (as of March 31, 2015)

Murata Manufacturing Co., Ltd.

Trade Name: Murata Manufacturing Co., Ltd.

Location of Head Office: 10-1, Higashikotari 1-chome, Nagaokakyo-shi, Kyoto

Date of Incorporation: December 23, 1950

Common Stock: ¥69,377 million

President Statutory Representative Director: Tsuneo Murata

Murata Locations: Americas: 15, Europe: 14, Greater China and East Asia: 30, Japan: 31 (except Murata Manufacturing Co., Ltd.), Southeast Asia and South Asia: 15

Number of Employees: 51,794 (consolidated basis)

Function: Research, Production and Sales of Electronic Devices made from fine ceramics

Products: Monolithic Ceramic Capacitors, SAW Filters, Ceramic Resonators, Piezoelectric Sensors, Ceramic Filters, Piezoelectric Buzzers, Short-range Wireless Communication Modules (including Bluetooth® Modules), Multilayer Ceramic Devices, Connectors, Isolators, Power Supplies, Circuit Modules, EMI Suppression Filters, Inductor (coils), Sensors