"Leading Edge Process for Lyophilization"

|

The powder that is obtained using conventional lyophilization

technologies, such as a freeze-drying and a spray-drying,

presents problems like differences in concentration, low

solubility, and inhomogeneity.

We, ULVAC, have solved those problems, utilizing the

technology that renders liquids directly dry. Then, we also

incorporate a fully packaged process system for sterile

production including powder filling and capping. Apply to

not only pharmaceuticals, but also food processing, fine

chemicals and electrical materials.

|

|

Utilizing Sublimation Utilizing Sublimation

|

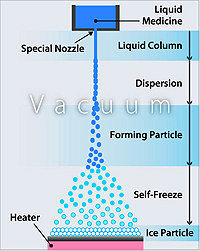

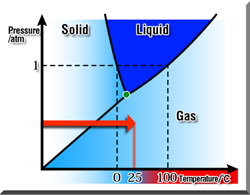

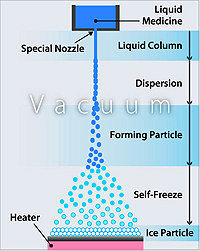

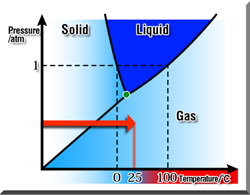

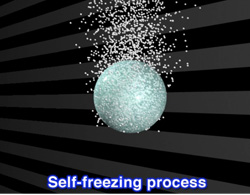

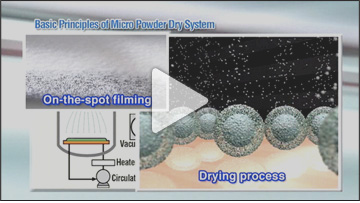

Sublimation that is the process of

immediate transition of a substance

from the solid-state to the gas-state, is

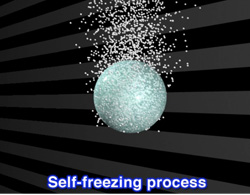

utilized in µPD. Therefore, spherical

shape powder by self-freezing in air

under vacuum is obtained, so that the

process of µPD is an epoch-making one

as a novel lyophilization technology. |

Main Features Main Features

|

The µPD has the unique technologies

that consist of a water particle generation,

a self-freezing and others.

|

PAGE TOP >

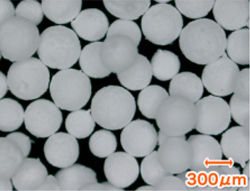

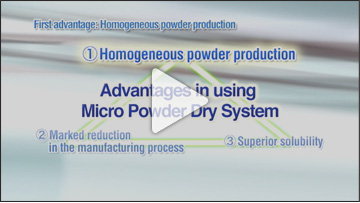

Small particle sized and homogeneous powder production Small particle sized and homogeneous powder production

|

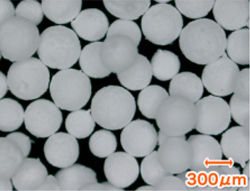

High speed drying due to larger surface

area of frozen material causes a very

sharp profile of particle size distribution

and no concentration gradient of

powder. It means that these particles

have high uniformity in particle size and

very homogeneous concentration of

powder by freezing from liquid droplet. |

Marked reduciton in the manufacturing process Marked reduciton in the manufacturing process

|

Additional production process like milling, classifying, etc. can be reduced.

Furthermore, very few loss and high process yield are carried out. |

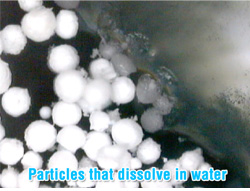

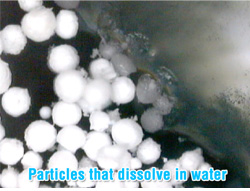

Superior Solubility Superior Solubility

|

High speed drying due to larger surface

area of frozen material, contributes to

superior solubility.

|

PAGE TOP >

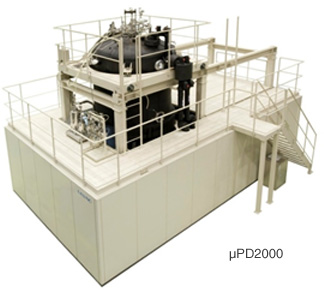

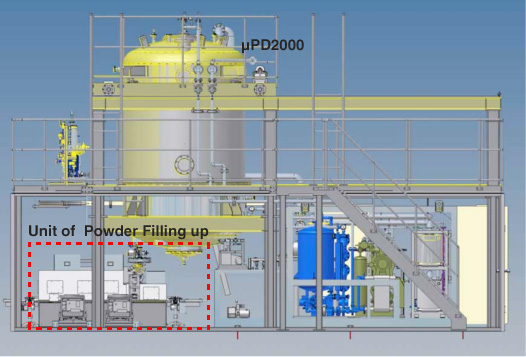

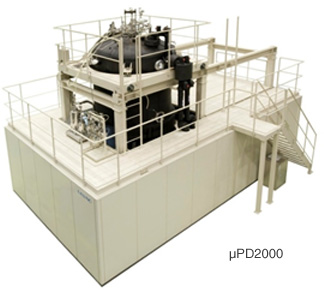

Line Up of µPD Series Line Up of µPD Series

|

The μPD Series are the

refined equipment using

self-freezing in practical

applications. |

|

[Specifications] |

| |

Equipment for

Mass-production |

Compact Equipment for

Experiment |

| Model |

µPD2000 |

µPD400 |

| Particle size |

100 to 400µm |

| Capacity |

150L/Batch |

5L/Batch |

| Shelf temperature control range |

-50 to 60℃ |

-40 to 60℃ |

| Vacuum control range |

5 to 30Pa |

| Cold trap temperature |

-65℃ |

-60℃ |

| Required space[mm] |

5600W×8200L×6800H |

1600W×2150L×3300H

|

|

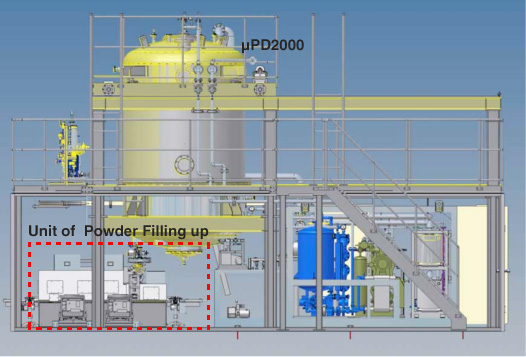

Turn Key System Turn Key System

Closed system of sterile pharmaceutical production is realized |

|

■ Unit of Powder Filling up

|

[Specification] |

| Particle size |

200 to 300µm |

| Vessel |

φ24.3[vial-bottle] |

| Tact speed |

2vials/(min・head) *100mg-filling up |

| Filling up volume |

100 to 1000 mg |

| Accuracy |

±0.5% |

|

|

PAGE TOP >

| One of the most important application utilizing µPD is the sterile pharmaceutical production. |

| Turn key system of µPD has been constructed aiming at advance into Global Market. |

| Those technologies which contribute to novel pharmaceutical production using extremely small sized powder, are applied for not only conventional freeze dry processes(Lyophilization)but also general splay-dry and vacuum-dry ones. |

| The µPD technology is also applicable for Health care materials, Foods, Cosmetics, and Electronic material productions as well as pharmaceutical one. |

|

PAGE TOP >

|

|

Utilizing Sublimation

Utilizing Sublimation

Main Features

Main Features

Small particle sized and homogeneous powder production

Small particle sized and homogeneous powder production

Marked reduciton in the manufacturing process

Marked reduciton in the manufacturing process

Superior Solubility

Superior Solubility

Line Up of µPD Series

Line Up of µPD Series

Turn Key System

Turn Key System

ULVAC, Inc. All rights reserved.

ULVAC, Inc. All rights reserved.