High Performance Materials

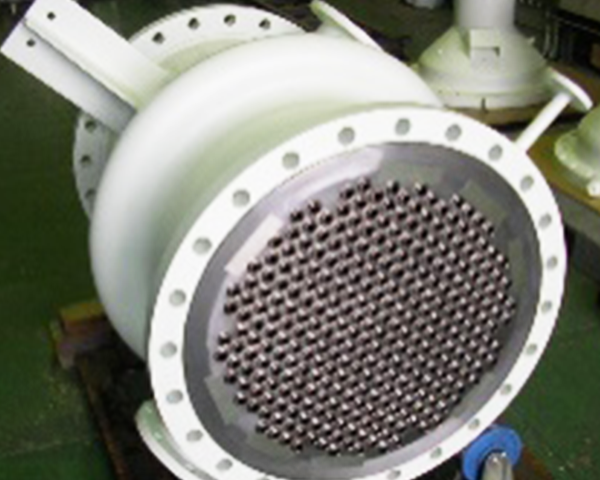

Heat Exchanger

[Ta] [Nb]

Ta/Nb/Zr/Ti heat exchangers from ULVAC use welds developed from vacuum techniques and are subject to a rigorous inspection system. ULVAC can boast of over 40 years of achievements in the manufacture of heat exchangers, and its products are highly rated in the chemical, pharmaceutical, and other industries.

Welding techniques

High quality atmosphere-controlled in-chamber welding

As tantalum, niobium, titanium, and zirconium are highly active metals, welding in the air causes contamination by atmospheric gases, preventing the construction of high quality welded structures. ULVAC conducts all its welding of active refractory metal either in inert gas substitution chambers that are highly atmosphere-controlled or by using electron beam welding, enabling the production of extremely high quality welded structures without contamination.

Control of characteristics after welding

To control contamination, the hardness of tantalum is controlled within base material + 40 HV, and the O and N increase amount within 100 ppm.

Comparison of welded portions of tantalum

<Hardness>

In-house control value: Base material + 40 HV

(Unit: HV)

| Base material | Welded portion | Difference | |

|---|---|---|---|

| ULVAC | 115 | 135 | 20 |

| Manufacturer A | 120 | 153 | 33 |

| Manufacturer B | 100 | 476 | 376 |

<Analysis>

In-house control value: O, N = Base material + 100 ppm (Unit: ppm)

(Unit: ppm)

| O | N | |

|---|---|---|

| ULVAC | +30 | +30 |

| Manufacturer A | +100 | +40 |

| Manufacturer B | +200 | +250 |

Material characteristics

The values below are officially recognized in the processes from “dissolution” through “rolling” to “welding” for Ta products of ULVAC. All processes are conducted in our plants.

<Tantalum>

| RT | 100℃ | 200℃ | 300℃ | Remarks | |

|---|---|---|---|---|---|

| Modulus of longitudinal elasticity(N/mm2) | 185000 | 183000 | 180000 | 177000 | From in-house data |

| Allowable stress (N/mm2) |

58 | 51 | 51 | 55 | Conforming to ASME* Code From in-house data |

| Yield point (N/mm2) |

170 | 147 | 147 | 167 | From in-house data |

* ASME:American Society of Mechanical Engineers

Coil type heat exchanger

Ta coil:Φ48.6mm × t1.5 220℃ 0.74MPa

Structures of tantalum foils with different grain sizes after pressing

Φ1500mm × 2500L Class 1 pressure vessel